Does an oil-free twin-screw air compressor truly achieve "complete oil-free" operation? What are the criteria for this assessment?

Understanding Whether Oil-Free Twin-Screw Air Compressors Truly Achieve "Complete Oil-Free" Operation

Oil-free twin-screw air compressors are widely used in industries that demand clean compressed air, and understanding whether such equipment can achieve a condition often described as "complete oil-free" is essential for selecting the right solution. Haidebao specializes in a full range of high specification aerodynamic products for gas compressor systems, providing research and development, design, manufacturing, marketing, and service support. This background ensures that discussions on oil-free systems remain grounded in practical engineering considerations. In actual industrial environments, achieving a completely oil-free condition involves not only the mechanical structure of the compressor but also the system configuration, filtration, and standards used to define oil content.

Definition of Oil-Free Operation in Industrial Standards

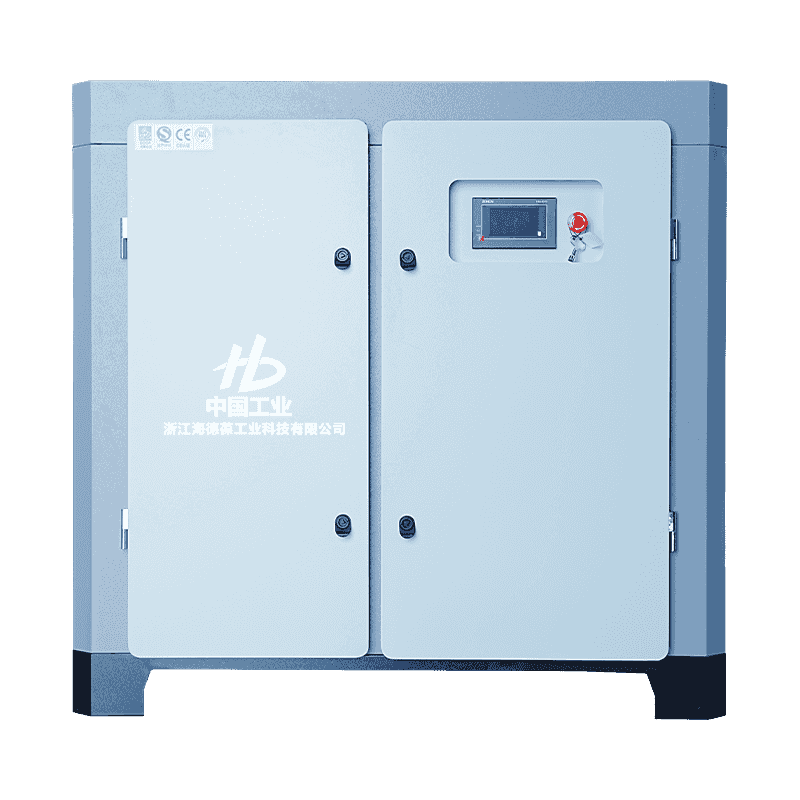

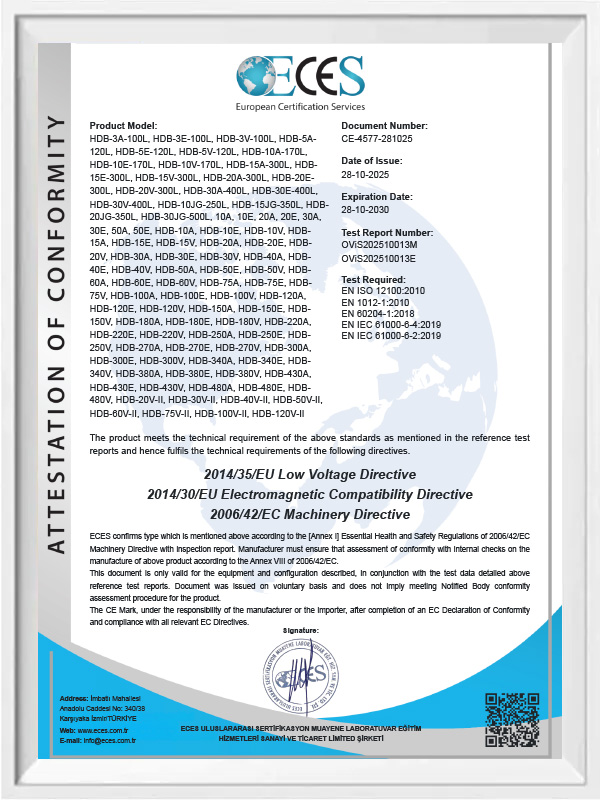

The term "oil-free" is often associated with ISO 8573-1:2010, which defines various classes of compressed air purity. For oil-free compressors, the most commonly referenced categories are Class 0 and Class 1 for total oil content. Class 0 refers to the strictest limit agreed upon between the user and manufacturer, and it typically requires extremely low levels of oil measured in mg/m³. Class 1 allows a small but controlled amount of oil content. These classifications consider both oil aerosols and oil vapors, ensuring a comprehensive evaluation. Understanding these metrics is essential because a compressor marketed as oil-free may still operate within Class 1 rather than Class 0 depending on the filtration and measurement technique. Haidebao’s involvement in system-level design ensures that the compressor and filtration stages align with these international standards.

Mechanical Structure of Oil-Free Twin-Screw Compressors

Oil-free twin-screw compressors typically use dry-running rotors, meaning no lubricating oil enters the compression chamber. Instead, they rely on timing gears, bearings, and specialized coatings to ensure proper rotor alignment. The absence of oil in the chamber greatly reduces the risk of oil contamination in the compressed air. Nonetheless, while the compression chamber is oil-free by design, other components in the system may still contain lubricants such as gearbox oil. The separation of these sections is critical for achieving high levels of air purity. Haidebao’s engineering approach emphasizes precision in the rotor profile, surface materials, and sealing structures, all of which contribute to stable operation without oil entering the airflow.

Factors That May Introduce Trace Oil Into the System

Even with oil-free compression mechanisms, trace oil can sometimes enter the airflow through system-level factors. These may include ambient environmental pollution, degradation of downstream filtration, or long-term wear of seals and bearings. Additionally, any auxiliary equipment installed in the system may release minimal oil vapors. Therefore, an assessment of oil-free performance must consider the entire air system rather than only the compressor. Haidebao offers integrated system solutions, supporting customers in designing configurations that minimize such risks and stabilize air quality.

Criteria for Assessing Whether Oil-Free Compressors Are Truly Oil-Free

Evaluation criteria typically include total oil content testing, measurement of particle levels, humidity level control, and compliance with internationally recognized compressed air purity standards. Testing methods often involve specialized analyzers designed to detect both aerosol and vapor-phase oil. Certification from third-party testing organizations is also a common practice for validation. The following table illustrates common purity classifications for reference:

| ISO 8573-1 Class |

Total Oil Content (mg/m³) |

Application Context |

| Class 0 |

User and manufacturer agreement |

High sensitivity operations |

| Class 1 |

≤ 0.01 |

General high-purity processes |

| Class 2 |

≤ 0.1 |

Standard industrial equipment |

These criteria make it possible to determine whether the compressor system meets the required oil-free level. Haidebao’s aerodynamic product capabilities allow system configurations that align accurately with these established classes.

How Haidebao Supports Oil-Free System Performance

Given Haidebao’s expertise in aerodynamic products for gas compressor systems, the company provides comprehensive technical support for selecting compressors, evaluating purity requirements, and designing complete systems. By integrating proper filtration, control systems, and monitoring solutions, Haidebao helps customers create air systems that maintain consistent oil-free conditions. System engineering, testing capabilities, and lifecycle service contribute to maintaining stable operation across various applications.

Practical Recommendations for Users

For users who seek to verify whether an oil-free twin-screw compressor can achieve operational goals, it is recommended to conduct third-party purity testing, evaluate filtration performance regularly, and ensure that the system is configured following ISO purity standards. Haidebao’s involvement in system research and manufacturing supports users in making informed decisions and maintaining long-term system stability. With clearly defined operational expectations and validated measurement methods, customers can accurately determine whether the compressor fulfills oil-free requirements.

How can I determine if the compressed air quality of an oil-free twin screw air compressor is up to standard?

Key Understanding of Compressed Air Quality Evaluation

Determining whether the compressed air quality of an oil-free twin screw air compressor meets required standards involves a combination of measurement, system inspection, and adherence to internationally recognized classifications. Oil-free technology aims to reduce the possibility of oil entering the compression chamber; however, purity evaluation must cover the entire air system. Haidebao specializes in high specification aerodynamic products for gas compressor system research, design, manufacturing, marketing, and service, enabling the company to support users with reliable guidance on compressed air performance and quality assessment. This article explains how to practically determine whether the compressed air generated by such a system meets industry expectations, especially in applications where air purity is essential.

Understanding Applicable Air Quality Standards

The primary reference used to evaluate compressed air quality is ISO 8573-1, which defines different purity classes for particles, water, and total oil content. Users should first identify the purity requirement for their application, because different industries, such as electronics, pharmaceuticals, or food processing, expect varying levels of control over contaminants. Oil-free twin screw compressors are often configured to achieve Class 0 or Class 1 for total oil content when tested under standardized conditions. Haidebao’s system knowledge helps integrate compressors and treatment components so the complete setup aligns with chosen air quality classifications. Understanding these standards ensures that evaluation is based on measurable criteria rather than general assumptions.

Measurement of Total Oil Content in Compressed Air

Testing total oil content is central to assessing compliance. Measurements typically include oil aerosols and oil vapors, and proper sampling techniques are essential for reliable results. Specialized analyzers or third-party testing agencies conduct sampling at specific points in the air system. Users should note that even with oil-free compression, oil vapors from ambient air or adjacent machinery can influence readings. To support accurate testing, Haidebao’s system design approach pays attention to air intake positioning, filtration layout, and service accessibility. Once measurements are obtained, they can be compared with standardized purity classes.

| ISO 8573-1 Class |

Total Oil Content (mg/m³) |

Typical Use Cases |

| Class 0 |

As agreed between manufacturer and user |

Sensitive manufacturing environments |

| Class 1 |

≤ 0.01 |

High-purity production lines |

| Class 2 |

≤ 0.1 |

General industrial systems |

This table provides a general overview that allows users to compare test results with accepted thresholds. Haidebao helps customers configure systems capable of achieving these categories consistently.

Inspection of Filtration and Dryer Components

Even if the compressor itself is designed as oil-free, downstream equipment plays a decisive role in final air quality. Filters, adsorption dryers, refrigeration dryers, and condensate separators contribute to removing particles, water, and trace oil vapors. To confirm that compressed air is up to standard, users must inspect the condition, installation direction, and service schedule of these components. Wear, saturation, or contamination of filter media may reduce performance. Haidebao’s aerodynamic product expertise includes system matching suggestions that help customers select appropriate filtration grades and ensure that installation meets operational demands.

Evaluating System Integration and Piping Conditions

Air quality assessment should also consider the physical configuration of the entire compressed air pipeline. Long pipe lengths, dead zones, oil-lubricated equipment connected to the same network, and aging seals can influence purity. Residual oil from older systems may be released when pressure fluctuates. Therefore, confirming that pipelines are cleaned, corrosion-free, and properly drained is an essential step. Haidebao’s comprehensive support in system design helps reduce potential contamination points and enhances overall stability in purity-sensitive industries.

Routine Monitoring and Maintenance as Quality Assurance

Even systems performing well after installation may experience gradual changes over time. Routine monitoring, logging of pressure dew point, filter differential pressure, and periodic purity testing allow users to confirm ongoing compliance. Maintenance schedules recommended by manufacturers should be followed to maintain predictable performance. Haidebao’s service capabilities support users in long-term monitoring by offering guidance on inspection intervals, component replacement cycles, and system optimization strategies.

Practical Steps for Users to Confirm Compliance

To determine whether compressed air quality meets requirements, users can take several practical steps: verify the purity class required for the intended process, conduct standardized oil content testing, ensure all filtration and drying components function within expected ranges, inspect pipelines for contamination risks, and maintain proper documentation of system performance. Haidebao’s experience in aerodynamic product development and system-level engineering ensures that customers receive informed support while identifying improvement opportunities. With systematic evaluation and appropriate testing, users can confidently determine whether their oil-free twin screw air compressor delivers the air quality needed for their application.

English

English Español

Español عربى

عربى