What Are the Actual Displacement and Energy Efficiency Performance of the 75HP Micro-Oil Twin Screw Single Stage Compressor?

Overview of Displacement Performance in Industrial Compressors

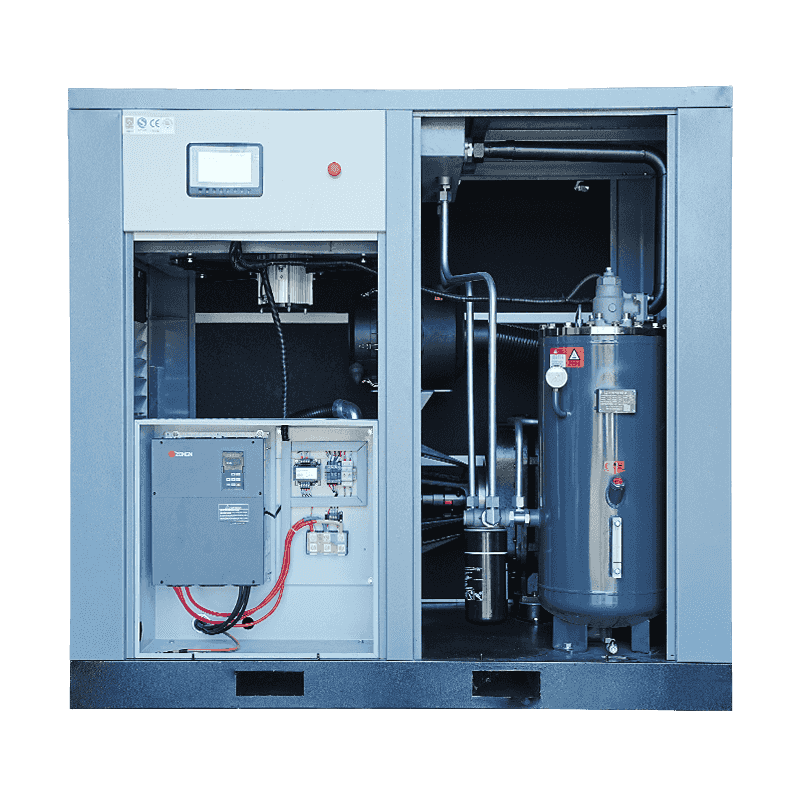

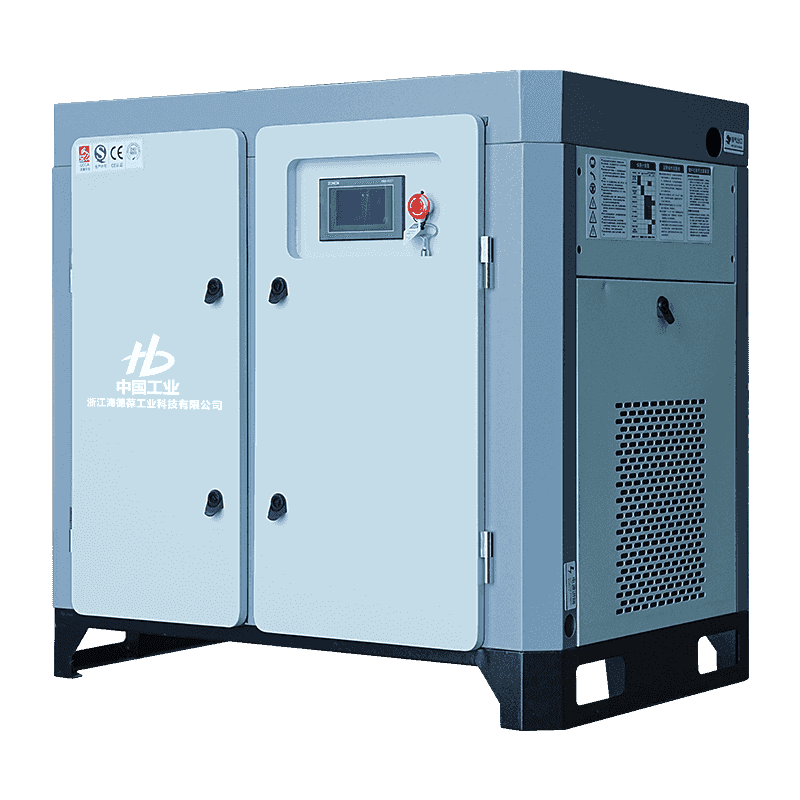

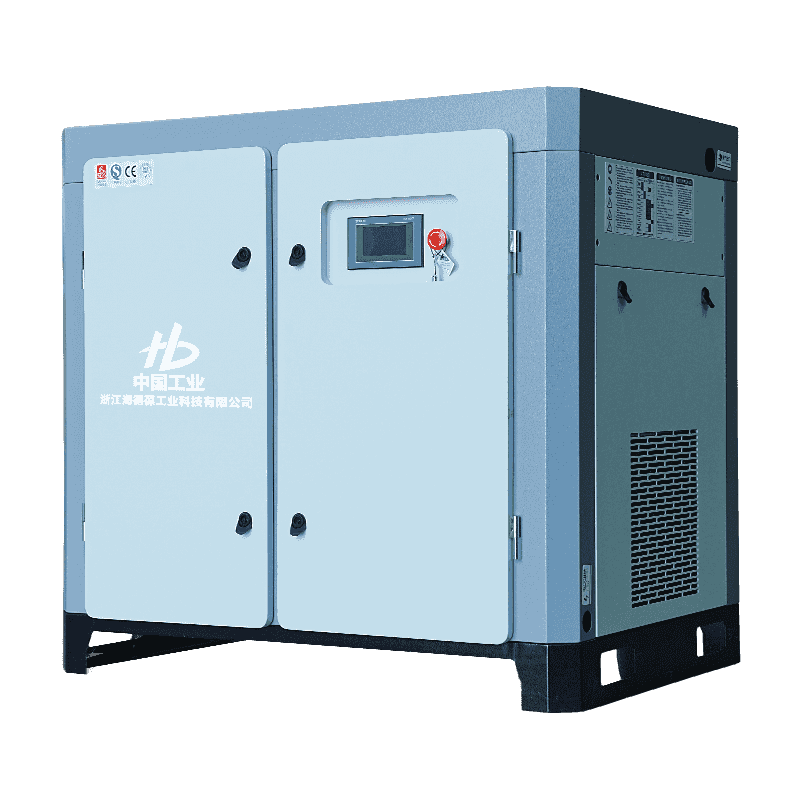

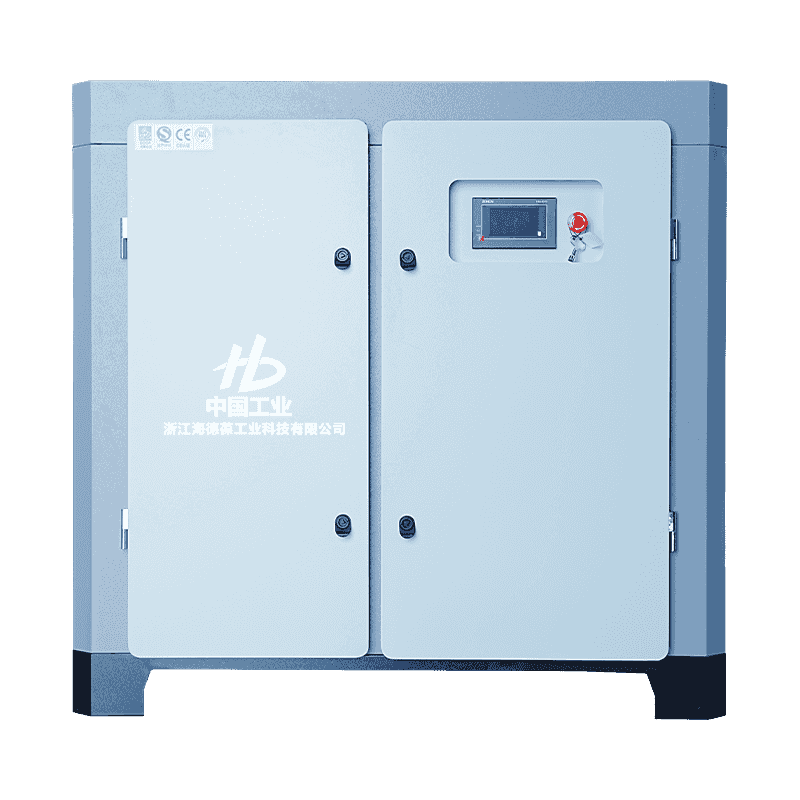

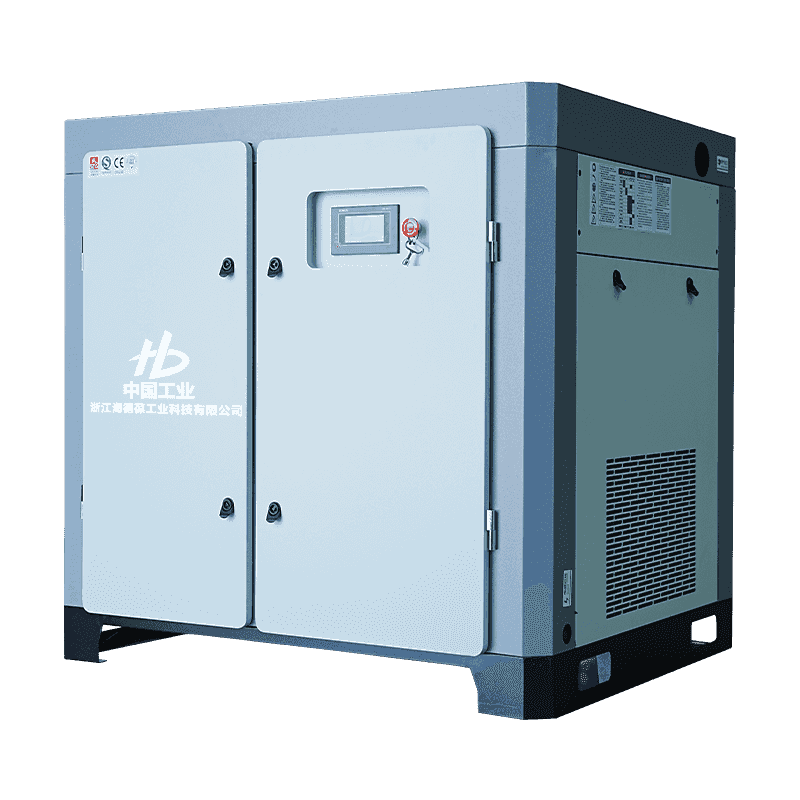

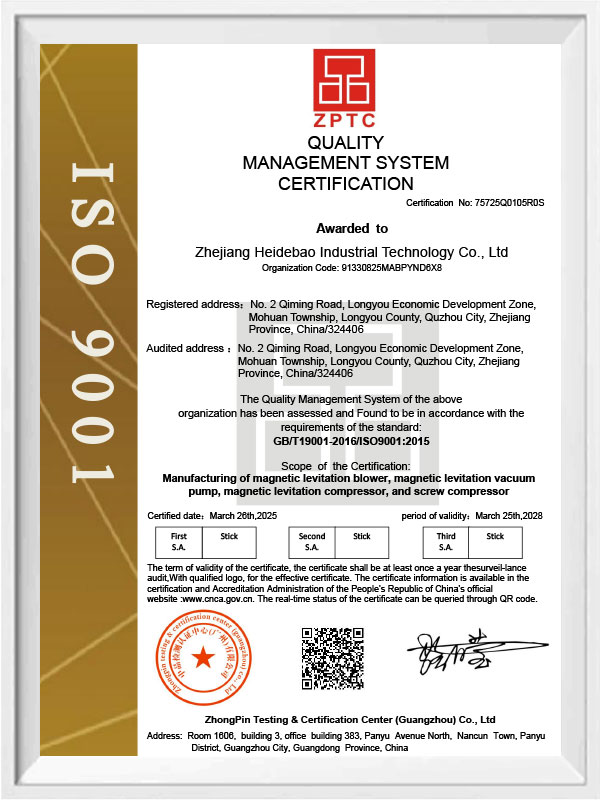

The displacement of an industrial air compressor is a key indicator that reflects its capability to deliver a stable and sufficient volume of compressed air under continuous operation. For the 75HP micro-oil twin screw single stage compressor developed by Zhejiang Haidebao Industrial Technology Co., Ltd., displacement performance is closely tied to the advanced mechanical design and fluid dynamics optimization of the unit. As a manufacturer located in Quzhou City, Zhejiang Province, Haidebao integrates its production knowledge with engineering analysis tools to ensure consistent gas output. The application of finite element analysis (CAE) helps evaluate airflow behavior and rotor performance under real-world load conditions, allowing the compressor to maintain a steady displacement range even during extended operation. This ensures that industries requiring high pressure and high flow can rely on stable and predictable gas supply.

Fluid Mechanics Optimization and Its Effect on Airflow Output

The 75HP micro-oil twin screw single stage compressor is designed according to fluid mechanics principles to reinforce its actual displacement capability. By optimizing the rotor profile and internal air passage structure, the compressor reduces flow turbulence and enhances volumetric efficiency. This controlled and efficient air movement ensures that the machine releases a stable volume of compressed air while reducing loss caused by internal leakage or friction. The stable airflow profile becomes especially important for applications that require continuous operation, where consistent displacement supports equipment performance on production lines. The fluid mechanics-based adjustments enable the compressor to function efficiently under high load and high pressure, further illustrating the relationship between structural design and output stability.

Role of CAE Finite Element Analysis in Predicting Displacement Stability

CAE finite element analysis technology plays an important role in shaping the displacement performance of the 75HP model. By dividing structural components into small computed elements and simulating them under various pressures, temperatures, and airflow states, engineers can accurately predict how the compressor will behave under real industrial conditions. This includes evaluating deformation under load, identifying potential friction points, and understanding fluid distribution characteristics. As a result, the displacement capability of the compressor becomes more predictable and less affected by unforeseen mechanical stress. Zhejiang Haidebao Industrial Technology Co., Ltd. applies this technology during the design stage to reinforce the long-term reliability of airflow output, ensuring that the compressor provides stable displacement even when running at high capacity for long periods.

Energy Efficiency Driven by Micro-Oil Lubrication Technology

Energy efficiency in the 75HP micro-oil twin screw single stage compressor is supported by its advanced micro-oil lubrication system. The lubrication layer reduces rotor friction, helps maintain stable internal temperature, and assists in sealing the compression chamber. These factors enhance the machine’s volumetric efficiency and reduce energy losses. During long-term use, maintaining lower friction and consistent heat distribution allows the compressor to operate with less power consumption while still delivering the required displacement. This contributes to energy-conscious operation, especially in facilities where compressors run continuously. The optimized lubrication also lowers mechanical wear, reducing the energy penalty caused by aging components and supporting stable performance across an extended lifecycle.

Energy Efficiency Supported by Structural Optimization

Energy efficiency is not determined solely by lubrication technology; structural design also plays a major role in the 75HP compressor’s performance. The rotor geometry, air passage alignment, and frame rigidity are optimized through CAE modeling to minimize unnecessary energy consumption. By ensuring smooth airflow circulation and reducing pressure drops within the internal channels, the system requires less power to achieve the same output. This structural refinement contributes to predictable energy consumption patterns, which helps industries control operational expenses. In high-load environments, these advantages become more noticeable, as the compressor sustains stable energy efficiency even under demanding operating conditions.

| Performance Indicator |

75HP Micro-Oil Twin Screw Single Stage Compressor |

Conventional Industrial Compressor |

| Displacement Stability |

Stable output under high load |

Greater fluctuations during long operation |

| Energy Efficiency During Continuous Use |

Supported by micro-oil lubrication and optimized channel design |

Often affected by mechanical wear and heat buildup |

| Internal Heat Control |

Improved through controlled lubrication and CAE optimization |

Temperature variation influences consumption |

| Mechanical Wear Impact |

Reduced due to lubrication and structural optimization |

Moderate to high impact depending on maintenance |

Interaction Between Displacement and Energy Consumption in Long-Term Use

In industrial equipment, displacement and energy efficiency are closely connected. For the 75HP micro-oil twin screw single stage compressor, stable displacement is achieved without excessive energy use due to the balanced design of the compression mechanism. The system prevents unnecessary load spikes, allowing the motor to operate at controlled levels. This relationship reduces the overall power demand, especially during long-term operation where instability can lead to increased energy consumption. Zhejiang Haidebao Industrial Technology Co., Ltd. incorporates engineering strategies that ensure the rotor system, lubrication circuit, and pressure control system work in coordination, resulting in predictable efficiency during continuous operation.

Long-Term Operating Benefits in Industrial Environments

Industrial environments that require high-pressure gas sources often face challenges related to energy consumption and equipment stability. The 75HP micro-oil twin screw single stage compressor addresses these challenges by combining optimized displacement performance with consistent energy consumption control. The system’s CAE-driven structure ensures that it withstands high load conditions without sacrificing airflow consistency, while the micro-oil lubrication minimizes friction-related losses. Over long operational cycles, these features contribute to a reduction in operating expenses and a more stable production process. This combination makes the compressor suitable for facilities prioritizing dependable air supply and energy-conscious operation.

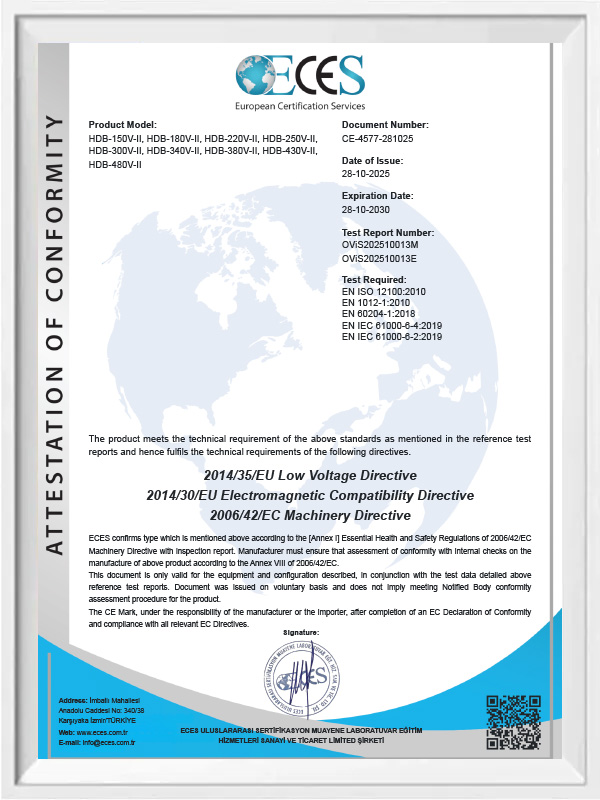

Key Features That Influence Overall Performance

The actual displacement and energy efficiency of the 75HP micro-oil twin screw single stage compressor are influenced by several coordinated design elements. The streamlined airflow channels reduce turbulence, while the micro-oil lubrication system provides consistent rotor support. CAE modeling ensures that compressive forces and heat distribution remain balanced, lowering the likelihood of performance loss during extended operation. These engineering considerations reflect the manufacturing strengths of Zhejiang Haidebao Industrial Technology Co., Ltd., which integrates fluid mechanics and structural simulation into its product development to enhance operational stability. As a result, the compressor offers dependable displacement and energy-conscious performance across various industrial environments requiring stable and continuous gas output.

English

English Español

Español عربى

عربى