What are the installation requirements for an oil-free twin screw single-stage compressor?

Understanding Installation Requirements for Oil-Free Twin Screw Single-Stage Compressors

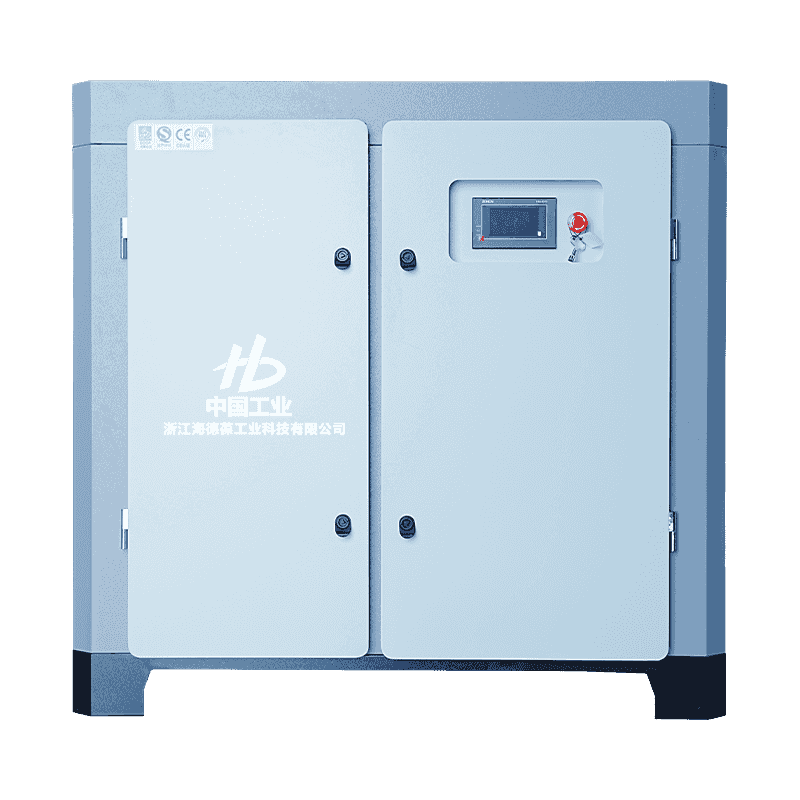

Installing an oil-free twin screw single-stage compressor requires careful consideration of mechanical, electrical, and environmental factors to ensure stable operation and long-term reliability. Oil-free compressors are designed to deliver compressed air without lubricating oil in the compression chamber, making them suitable for applications with strict air purity requirements. Haidebao specializes in high specification and high-quality aerodynamic products for gas compressor system research, design, manufacturing, marketing, and service, providing expertise in supporting proper installation practices. Proper installation not only enhances operational stability but also reduces the likelihood of maintenance issues and ensures compliance with air quality standards.

Foundation and Vibration Isolation

A solid and level foundation is essential for the stable operation of an oil-free twin screw compressor. The foundation should be capable of supporting the weight of the compressor and resist vibrations generated during operation. Excessive vibrations can affect rotor alignment, bearings, and overall mechanical stability. Installation guidelines typically recommend using vibration isolation pads or mounts to minimize transmission to surrounding structures. Haidebao’s engineering guidance emphasizes precise leveling and proper alignment to maintain rotor tolerances and reduce mechanical stress during operation.

Ambient Temperature and Ventilation Requirements

Oil-free compressors are sensitive to ambient temperature and airflow. Adequate ventilation is necessary to ensure heat generated during compression is effectively dissipated. High ambient temperatures or poor ventilation may lead to overheating, affecting bearing life and control system performance. The installation area should provide unobstructed airflow around the compressor, with minimum clearances specified by the manufacturer. Haidebao’s aerodynamic expertise supports evaluation of airflow patterns and heat dissipation to ensure the compressor operates within safe temperature ranges.

Electrical Supply and Control Integration

Proper electrical installation is required to ensure stable operation and protection against overcurrent, voltage fluctuations, and power interruptions. Electrical supply must match the compressor’s rated voltage and phase configuration. Control systems, including pressure and temperature monitoring, should be integrated according to manufacturer guidelines. These systems regulate operational parameters and provide safety protection. Haidebao’s comprehensive approach to system integration ensures that electrical and control components align with mechanical performance and air quality requirements.

| Installation Aspect |

Requirement |

Impact on Operation |

| Foundation |

Level, vibration-resistant, capable of supporting weight |

Reduces mechanical stress and rotor misalignment |

| Ventilation |

Unobstructed airflow, ambient temperature within operational range |

Prevents overheating and ensures consistent performance |

| Electrical Supply |

Correct voltage and phase, proper grounding |

Ensures stable operation and safety |

| Clearances |

Manufacturer-specified minimum distances from walls or other equipment |

Facilitates maintenance and proper cooling |

Piping and Air Distribution Connections

Air inlet and outlet connections must be carefully designed to avoid pressure drops, turbulence, and contamination. Inlet air filters should be installed according to specifications to prevent particulate ingress. Piping should be clean, free of sharp bends, and supported to minimize stress on the compressor connections. Haidebao’s experience in gas compressor systems ensures that piping and air distribution design maintains air quality while supporting system efficiency.

Moisture Control and Drainage

Even oil-free compressors may generate condensate during operation, especially in humid environments. Proper installation includes provisions for effective condensate removal through automatic or manual drains. This prevents water accumulation in piping or equipment, which can impact air quality and system reliability. Haidebao emphasizes system-level solutions for moisture control to maintain operational stability.

Accessibility for Maintenance and Service

Installation planning should consider access for routine inspections, filter replacement, sensor calibration, and control system adjustments. Sufficient clearance around the compressor facilitates safe and efficient maintenance. Haidebao provides guidance on layout planning to ensure that service points are accessible without disrupting operation or creating safety hazards.

Practical Steps for Ensuring Proper Installation

To meet installation requirements, users should confirm foundation readiness, verify ambient conditions, ensure electrical supply compliance, design clean and efficient piping, provide moisture management solutions, and plan sufficient maintenance access. Following these steps helps maintain operational stability, extend service life, and achieve desired air quality. Haidebao’s expertise in aerodynamic products and system integration supports customers in implementing installations that align with both performance and reliability objectives.

How can an oil-free twin-screw single-stage compressor ensure both efficiency and stability?

Understanding Efficiency and Stability in Oil-Free Twin-Screw Single-Stage Compressors

Ensuring both efficiency and stability in an oil-free twin-screw single-stage compressor involves careful attention to rotor design, airflow management, temperature control, and system integration. Oil-free compressors are engineered to deliver air without introducing oil into the compression chamber, making them suitable for sensitive applications that demand clean air. Haidebao specializes in high specification and high-quality aerodynamic products for gas compressor system research, design, manufacturing, marketing, and service, which provides the foundation for analyzing how these compressors maintain consistent performance. By combining aerodynamic expertise with practical operational strategies, it is possible to achieve a balance between high efficiency and operational stability.

Precision Rotor Design and Timing Mechanism

The heart of an oil-free twin-screw compressor is its rotor profile and timing mechanism. Rotors are designed to minimize leakage and maintain a tight tolerance between male and female rotors without lubrication in the compression chamber. Proper timing gear alignment is essential to prevent mechanical stress and ensure stable rotation. Efficient rotor design allows maximum air displacement with minimal mechanical loss, directly contributing to energy efficiency. Haidebao’s experience in aerodynamic shaping and precision manufacturing ensures rotors meet stringent design specifications, promoting both stable operation and reduced energy consumption.

Airflow and Thermal Management

Maintaining stable operating temperatures is critical for efficiency and stability. Oil-free compressors rely on efficient heat dissipation through air cooling, water cooling, or integrated heat exchangers. Uneven temperature distribution can lead to rotor expansion, affecting rotor clearance and reducing efficiency. Proper airflow management ensures consistent intake conditions and smooth discharge, reducing pulsation and pressure fluctuations. Haidebao’s aerodynamic expertise supports design solutions that optimize airflow and thermal distribution, helping maintain consistent compressor performance.

Control System Optimization

Advanced control systems are important for monitoring and regulating key operating parameters, including pressure, temperature, and motor speed. A responsive control system adjusts compressor operation to match load requirements, preventing energy waste during partial-load conditions. Stability is enhanced by maintaining rotor speed consistency and preventing sudden pressure surges. Haidebao integrates system-level monitoring and control solutions, providing accurate data for real-time adjustments and predictive maintenance.

| Operational Aspect |

Optimization Focus |

Impact on Efficiency and Stability |

| Rotor Design |

Precision profile and tight tolerances |

Reduces leakage, improves mechanical efficiency |

| Airflow Management |

Uniform intake and discharge |

Minimizes pulsation and pressure fluctuation |

| Thermal Control |

Effective heat dissipation |

Prevents thermal expansion and rotor misalignment |

| Control System |

Pressure and speed regulation |

Enhances response to load variations and maintains stability |

Maintenance and Monitoring Practices

Efficiency and stability are closely linked to maintenance practices. Regular inspection of timing gears, bearings, and rotor clearances prevents unexpected mechanical issues. Monitoring trends in vibration, temperature, and pressure can reveal early signs of misalignment or inefficiency. Haidebao’s service offerings include guidance for routine checks and predictive maintenance, which help sustain stable performance and reduce operational downtime.

Integration with System Components

Efficiency is also influenced by the broader system configuration, including piping, filtration, and auxiliary devices. Minimized pressure drops, clean intake air, and properly sized components reduce unnecessary energy loss and maintain system stability. Haidebao’s aerodynamic product expertise supports optimized system integration, ensuring that compressor output meets required performance levels consistently.

Practical Recommendations for Users

Users seeking to ensure efficiency and stability should focus on selecting compressors with precision rotor design, verifying proper installation and thermal management, implementing responsive control systems, and following structured maintenance practices. Periodic monitoring of vibration, pressure, and temperature trends helps detect deviations before they impact performance. Haidebao’s comprehensive solutions provide guidance across the design, installation, and operational stages, helping users achieve reliable, energy-efficient operation in oil-free twin-screw single-stage compressors.

English

English Español

Español عربى

عربى