Product Consultation

Your email address will not be published. Required fields are marked *

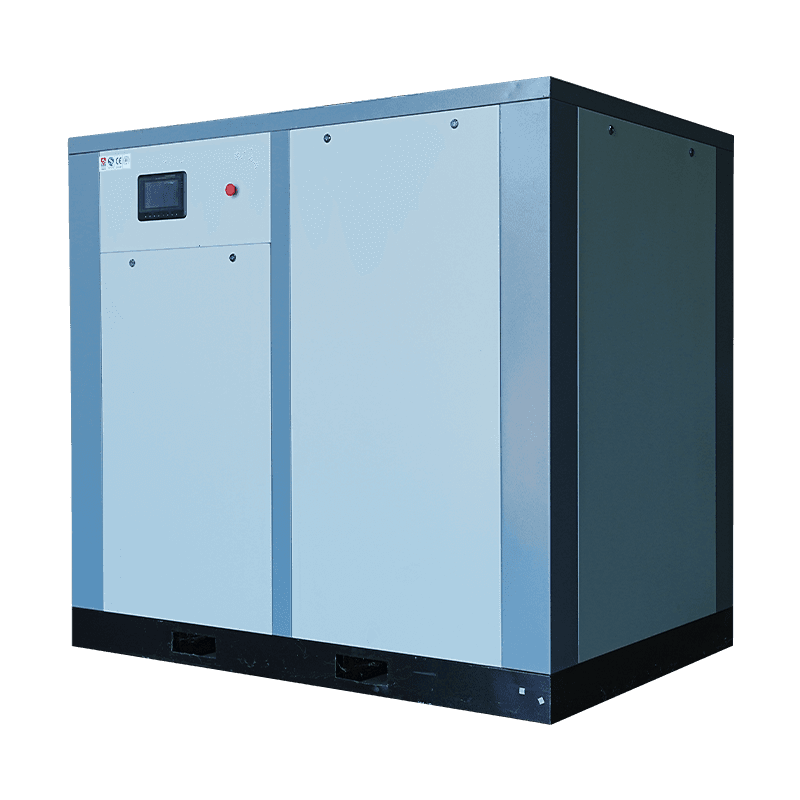

Micro-oil twin screw air compressors are widely used in industrial environments where continuous compressed air supply is required. During operation, the meshing of twin screws, motor rotation, and airflow movement inevitably generate vibration and noise. As equipment operating for extended periods, these compressors are typically designed with multiple structural and material considerations aimed at managing mechanical vibration and airborne sound. Whether these designs are effective depends on the integration of mechanical layout, damping components, enclosure structure, and system balance rather than a single isolated feature.

Vibration in micro-oil twin screw air compressors mainly originates from the rotating screw rotors, motor operation, and transmission components. As the screws rotate at high speed, even minor imbalance or alignment deviation can produce cyclic mechanical forces. Additionally, pressure pulsation generated during air compression contributes to dynamic loads on the compressor housing. These vibration sources are inherent to the compression process, which is why damping and isolation measures are commonly incorporated during the design stage.

The design of twin screw rotors plays an important role in controlling vibration. Modern micro-oil compressors typically use precision-machined rotors with controlled clearances to maintain stable meshing. Dynamic balancing processes are applied to reduce eccentric mass distribution, helping minimize rotational vibration. While this does not eliminate vibration entirely, it contributes to smoother operation and reduces the transmission of mechanical oscillations to the compressor frame.

Bearing systems support the rotating shafts and directly affect vibration behavior. In micro-oil twin screw air compressors, bearings are selected to handle axial and radial loads generated during compression. Proper bearing preload and lubrication help maintain stable rotor positioning. When bearings operate under controlled conditions, they reduce excessive shaft movement, which in turn supports vibration damping across the operating speed range.

The compressor frame and base structure act as the foundation for vibration control. Many micro-oil twin screw air compressors incorporate rigid frames combined with vibration-isolating mounts. These mounts, often made from elastomeric or composite materials, separate the vibrating compressor assembly from the floor or supporting structure. This isolation limits vibration transmission to the surrounding environment and contributes to more stable installation in industrial settings.

Flexible couplings and hoses are commonly used between key components such as the motor, compressor element, and discharge piping. These flexible connections absorb minor misalignments and dampen vibrational energy that would otherwise propagate through rigid connections. By interrupting direct vibration paths, flexible elements support overall system stability and reduce structure-borne noise.

Noise in micro-oil twin screw air compressors arises from several mechanisms, including mechanical contact, airflow turbulence, and pressure pulsation. Rotational noise from screws and motor components combines with aerodynamic noise generated as air is compressed and discharged. Understanding these noise sources allows designers to apply targeted noise reduction measures rather than relying on enclosure thickness alone.

Most micro-oil twin screw air compressors are equipped with acoustic enclosures designed to limit airborne noise emission. These enclosures often include layered panels with sound-absorbing materials on the interior surfaces. The combination of mass and absorption helps reduce sound reflection and transmission. Ventilation openings are typically designed with baffles or labyrinth structures to allow airflow while limiting direct noise escape.

Inside the compressor enclosure, sound-absorbing materials are strategically placed near noise-generating components. These materials help convert sound energy into heat through friction within porous structures. By reducing reverberation inside the enclosure, internal sound absorption contributes to lower external noise levels without restricting cooling airflow.

| Noise Source | Primary Origin | Mitigation Approach |

|---|---|---|

| Mechanical rotation | Screw rotors and motor | Dynamic balancing and enclosure absorption |

| Airflow turbulence | Compression and discharge paths | Optimized flow channels and silencers |

| Pressure pulsation | Compression cycles | Damping chambers and system tuning |

Air intake and exhaust points are significant contributors to noise emission. To address this, micro-oil twin screw air compressors often incorporate intake silencers and discharge mufflers. These components are designed to reduce sound energy generated by high-velocity airflow. By controlling noise at entry and exit points, overall sound levels are reduced without affecting compressor performance.

Cooling systems are essential for maintaining operating temperature but can introduce additional noise. Fan blade design, rotational speed, and airflow path all influence sound generation. Many compressors use optimized fan geometries and controlled airflow channels to reduce turbulence-related noise. This approach helps balance cooling requirements with acceptable noise characteristics.

Effective vibration damping and noise reduction are closely linked. Vibration can generate secondary noise when it excites panels or structural components. By reducing vibration at its source and isolating it from the enclosure, designers limit the potential for structure-borne noise. This integrated approach is commonly seen in micro-oil twin screw air compressors intended for indoor or noise-sensitive installations.

The effectiveness of built-in damping and noise reduction designs is influenced by installation conditions. Uneven foundations, rigid piping connections, or insufficient clearance around the compressor can reduce the benefits of internal design measures. Proper installation practices support the intended performance of vibration isolators and acoustic enclosures, allowing the compressor to operate within expected noise and vibration ranges.

Over time, wear of bearings, couplings, and mounts can alter vibration and noise behavior. While micro-oil twin screw air compressors are designed with damping features, their effectiveness depends on component condition. Regular inspection and timely replacement of worn parts help maintain stable operation and prevent gradual increases in vibration or noise levels.

When compared to reciprocating compressors, twin screw designs generally exhibit smoother airflow and lower vibration due to continuous compression rather than cyclic motion. The micro-oil lubrication approach further supports stable rotor operation by reducing friction and damping internal contact forces. These characteristics make twin screw compressors more suitable for environments where controlled vibration and noise are important considerations.

| Compressor Type | Vibration Characteristics | Noise Behavior |

|---|---|---|

| Micro-oil twin screw | Continuous, relatively stable | Managed through enclosure and silencers |

| Reciprocating | Cyclic and impact-related | Higher mechanical noise tendency |

Incorporating vibration damping and noise reduction features involves balancing cost, size, cooling efficiency, and maintenance accessibility. Thicker enclosures and heavier damping materials can reduce noise but may affect airflow or footprint. Designers of micro-oil twin screw air compressors typically aim for a balanced solution that addresses practical operating requirements without excessive complexity.

Micro-oil twin screw air compressors commonly incorporate a range of vibration damping and noise reduction designs, including balanced rotors, isolation mounts, acoustic enclosures, and airflow silencers. These features work together to manage the inherent mechanical and aerodynamic forces generated during operation. While actual performance depends on design quality, operating conditions, and maintenance, such compressors are generally structured to address vibration and noise as integral aspects of their overall system design.

How efficient is a twin screw air compressor in terms of energy consumption?

Does the micro-oil twin screw air compressor offer any practical advantages in terms of energy consumption control?

Your email address will not be published. Required fields are marked *

A dedicated after-sales service department is established, consisting of a professional sales team and skilled technical engineers. They are committed to providing year-round support, traveling to customer locations to deliver prompt and high-quality service.

Tel:86-0570-7221666

E-mail:[email protected]

Add: No.2 Qiming Road, Zhejiang Longyou Economic Development Zone, Mohuan Township, Longyou County, Quzhou City, Zhejiang Province, China