Noise and Vibration Levels of the Screw Compressor Laser Integrated Machine

Overview of Noise and Vibration Characteristics

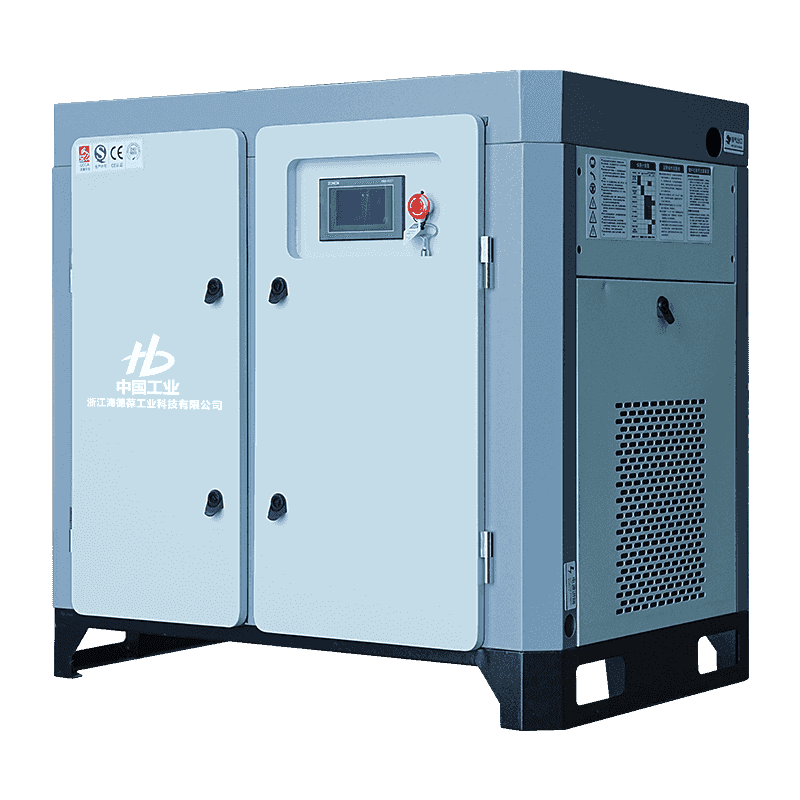

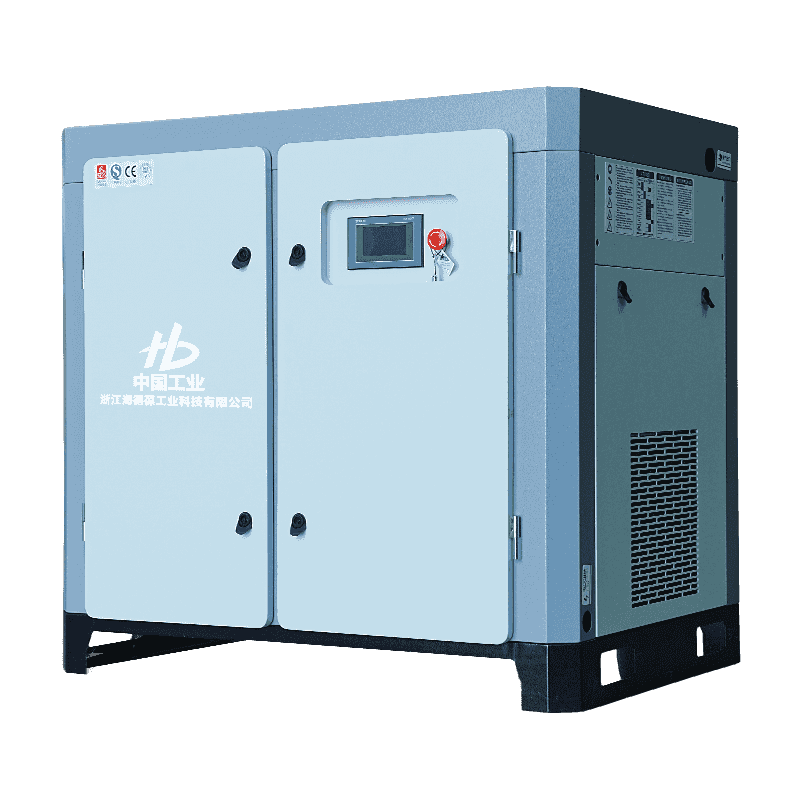

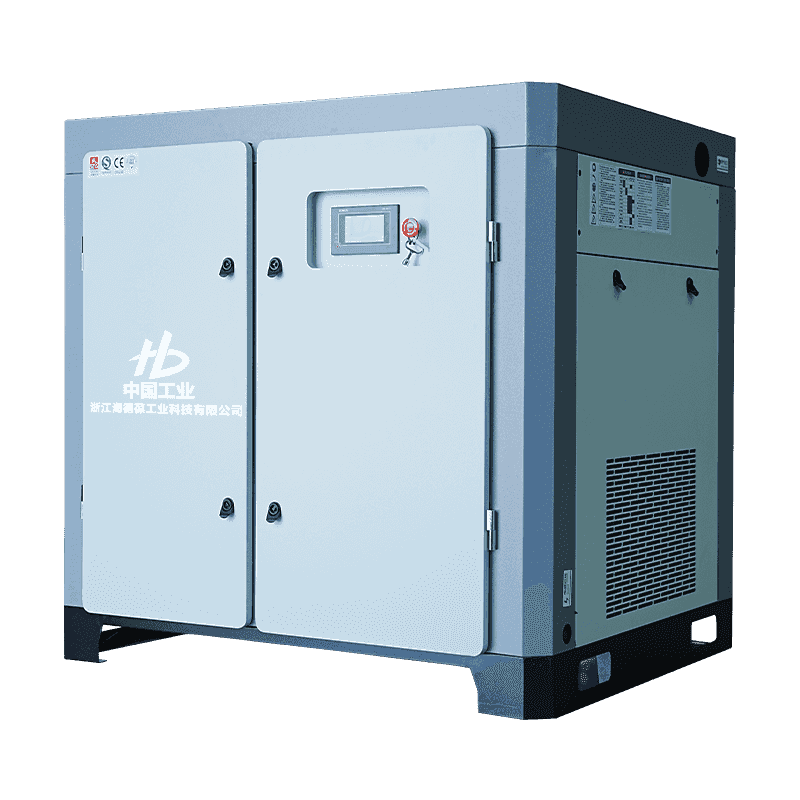

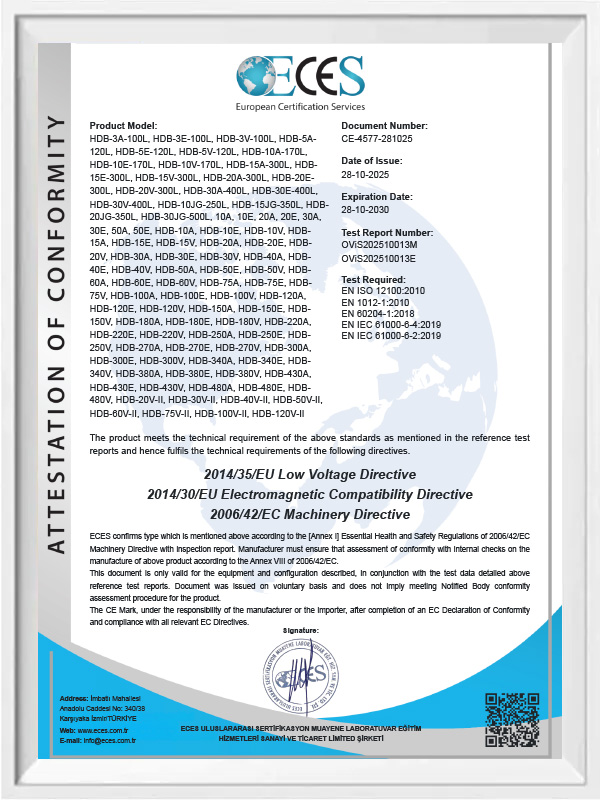

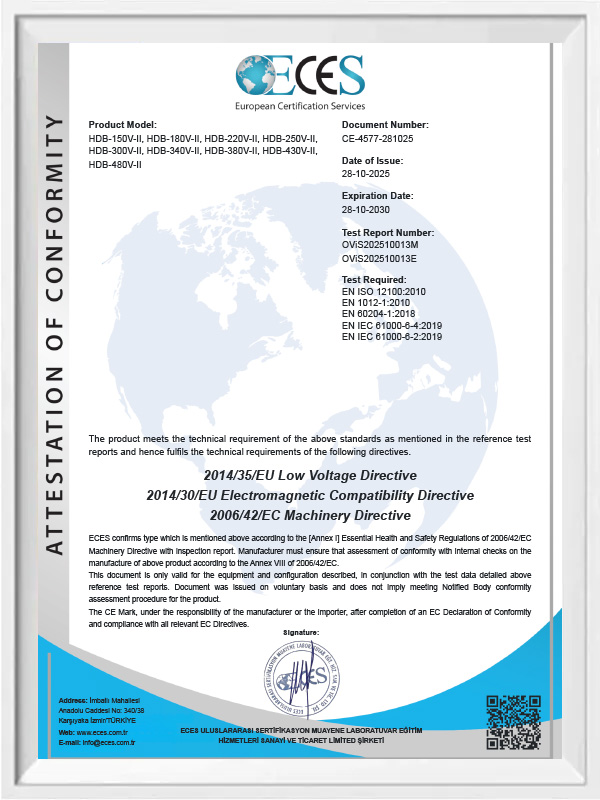

The Screw Compressor Laser Integrated Machine produced by Zhejiang Haidebao Industrial Technology Co., Ltd. incorporates a compact structural layout and a 15 kW motor that outputs 1.5 m³/min at 16 bar. This configuration is designed to support multiple industrial requirements for stable compressed air while maintaining controlled noise and vibration behavior during continuous operation. The integrated structure reduces the transfer of mechanical resonance between internal components, while the high-strength frame housing provides stable support. As a result, noise and vibration levels remain within a range that aligns with common industrial safety and comfort standards when the machine is running under load.

Influence of the High-Pressure Oil Separation System on Acoustic Performance

The machine features a built-in low-pressure dedicated oil separation system, using an oversized oil separator barrel and high-efficiency oil separation core. This setup maintains the exhaust oil concentration below 3 PPM, which not only improves air quality but also contributes positively to acoustic stability. Lower internal turbulence and reduced frictional disturbances within the air path help minimize unexpected noise peaks during long-term operation. The smoother airflow, made possible by the well-regulated oil management system, reduces the mechanical oscillations that often lead to vibration intensification in conventional configurations. Therefore, users experience consistent operational sound characteristics with fewer irregular fluctuations caused by oil-air interaction.

Cooling System Contribution to Stable Vibration Control

A carefully engineered cooling system is applied to ensure stable operation even when ambient temperatures reach 46°C. With the help of specialized coolant and optimized temperature control, the machine avoids excessive thermal expansion that could cause component misalignment. Stable temperatures inside the unit limit the growth of mechanical vibration, as components maintain their designed clearance and contact levels. Overheating can lead to uneven lubrication, rapid bearing wear, and increased vibration, but the integrated machine’s cooling approach keeps thermal stress under control. This has a substantial effect on maintaining predictable and acceptable vibration levels throughout long operational cycles.

Structural Layout and Frame Design for Noise Suppression

The outer housing uses industrial-grade materials designed to absorb part of the vibration energy generated by internal rotating components. The frame construction distributes loads evenly, reducing the structural resonance that typically amplifies noise within compressor enclosures. The low-pressure oil separation system, the rotor chamber, and the motor assembly are arranged in a balanced manner to prevent harmonic vibrations. This arrangement reduces the transfer of internal vibrations to the outer casing, lowering sound radiation to the surrounding environment. The close-coupled placement of major components also prevents airflow pulsation from causing acoustic amplification within the housing.

Typical Noise and Vibration Ranges During Operation

While actual performance depends on installation conditions, foundation quality, and load variations, typical noise and vibration ranges of this integrated machine fall within commonly accepted values for medium-power screw compressors. The following table summarizes general reference ranges based on similar machine types and configurations. These values help illustrate expected operational behavior under stable working conditions.

| Operating Condition |

Typical Noise Range (dB) |

Vibration Behavior |

| Rated Load at 16 bar |

68–75 dB |

Low, stable vibration with minimal fluctuations |

| Partial Load |

64–72 dB |

Stable vibration; reduced mechanical stress |

| High Ambient Temperature (up to 46°C) |

70–77 dB |

Controlled vibration due to stable cooling performance |

Impact of the Integrated Motor and Compressor Assembly

The integrated motor and compressor assembly uses direct coupling to minimize energy loss while also limiting unbalanced forces that can cause vibration. The motor’s performance stability helps reduce momentary torque fluctuations that otherwise increase noise in traditional belt-driven or indirect systems. Because the rotor and motor are matched for optimized alignment, rotational imbalance is minimized. This alignment helps maintain smooth operation, ensuring that vibration does not propagate aggressively throughout the frame. The low mechanical resistance across the direct connection also reduces audible mechanical interaction, contributing to a more controlled acoustic output.

Long-Term Operation Stability and Predictability

During long-term operation, the screw compressor laser integrated machine maintains stable noise and vibration characteristics due to the balanced design of its oil separation, cooling, and structural systems. Even during extended periods of high-load application, the consistent lubrication quality prevents sudden increases in friction noise or vibration surges. The machine’s thermal management helps prevent drift in mechanical alignment, which is often a leading cause of rising vibration levels over time. The machine design ensures that stable operation can be sustained without significant acoustic degradation, making it suitable for environments where noise and vibration control are essential for operator comfort and equipment reliability.

Installation Considerations That Affect Performance

Although the machine’s design inherently supports controlled noise and vibration behavior, installation conditions significantly influence actual performance. Proper foundation leveling, vibration-damping mounts, and sufficient ventilation space all contribute to maintaining optimal sound and vibration behavior. Environments with reflective surfaces may intensify perceived noise levels, while unstable or uneven floors can amplify vibration. When installed according to manufacturer recommendations, the machine demonstrates consistent acoustic output and vibration performance aligned with industry expectations for this power class.

English

English Español

Español عربى

عربى