Product Consultation

Your email address will not be published. Required fields are marked *

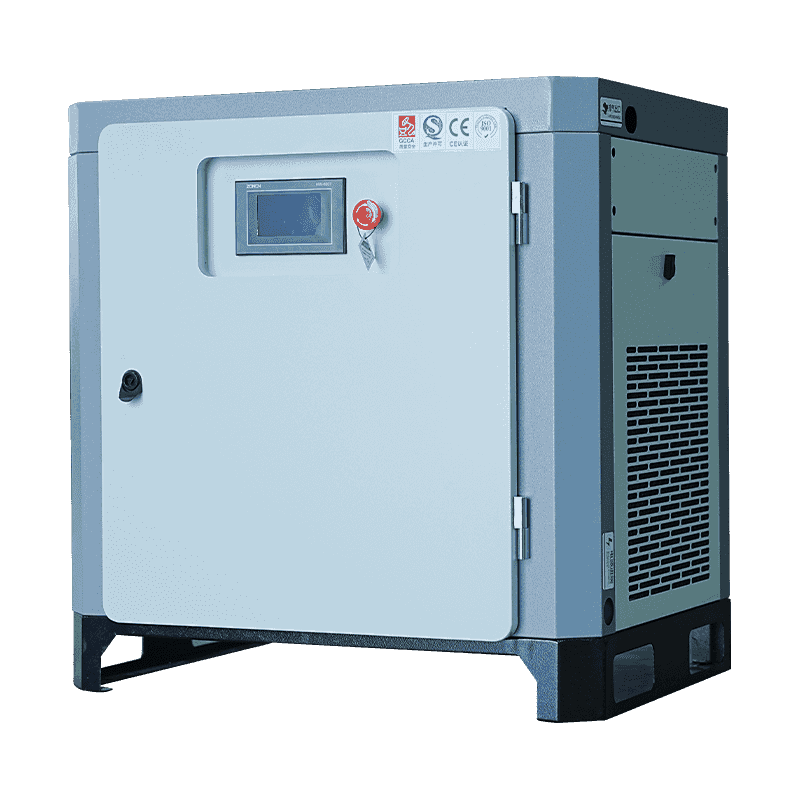

A twin screw air compressor is a type of positive displacement compressor commonly used in industrial applications for compressing air and gases. It operates using two interlocking helical screws, also known as rotors, which rotate in opposite directions. The main function of this type of compressor is to increase the pressure of air or gas by reducing its volume. Twin screw air compressors are widely used in various industries, including manufacturing, automotive, and energy sectors, for tasks such as powering pneumatic tools, supplying compressed air for industrial processes, and running air-driven machinery. One of the key concerns with using air compressors is their energy consumption.

The basic working principle of a twin screw air compressor involves the compression of air or gas by two helical rotors that rotate in opposite directions. As the rotors turn, they trap a volume of air between the rotor teeth, progressively moving it toward the discharge end where the air is compressed and expelled. The efficiency of a twin screw air compressor is largely influenced by the design of the rotors, the materials used, and the sealing mechanisms. These compressors can deliver high pressure with low energy input compared to other compressor types, such as reciprocating compressors, due to their continuous and smooth compression process.

Energy efficiency is a critical consideration for any industrial air compressor, as compressed air is often used in large quantities and can represent a significant portion of a facility’s energy consumption. Twin screw air compressors are generally regarded as more energy-efficient than other types of compressors due to their design and operational characteristics. However, several factors influence how efficient they are in terms of energy use, including the compressor's load profile, maintenance practices, and the type of application in which it is used.

There are several key factors that affect the energy efficiency of twin screw air compressors. Understanding these factors can help in optimizing the operation of the compressor and ensuring that it consumes the least amount of energy while delivering the required performance.

The size and capacity of a twin screw air compressor play a crucial role in its energy efficiency. Compressors that are too large for the required application may consume more energy than necessary because they are not operating at their optimum efficiency range. On the other hand, compressors that are undersized may struggle to meet demand, causing them to work harder and consume more energy to maintain the desired output. Selecting the right-sized compressor for a given application is essential for achieving optimal energy efficiency.

One of the most effective technologies for improving the energy efficiency of twin screw air compressors is the incorporation of a variable speed drive (VSD). A VSD adjusts the speed of the compressor’s motor based on the demand for compressed air, allowing the compressor to operate only at the necessary capacity. This reduces energy consumption during periods of low air demand and minimizes the energy waste associated with idling or over-compressing. Twin screw air compressors with VSDs can achieve significant energy savings, particularly in applications with fluctuating air demand.

The energy efficiency of a twin screw air compressor is also influenced by the operational conditions and the load profile of the system. Continuous, steady operation at a fixed capacity tends to be more energy-efficient than intermittent operation where the compressor is frequently cycling on and off. Systems that experience fluctuating or variable demand may benefit from a VSD or a load-unload control system that adjusts the compressor’s output in response to changing requirements. Properly managing the load profile ensures that the compressor operates efficiently and consumes minimal energy.

Routine maintenance and regular performance optimization are critical for maintaining the energy efficiency of a twin screw air compressor. Over time, components such as filters, lubricants, and seals can degrade, causing the compressor to work harder and consume more energy. For example, dirty filters or low-quality lubricants can increase friction, reduce airflow, and lower overall efficiency. Ensuring that the compressor is properly maintained and that any performance issues are addressed promptly can help maintain its energy efficiency throughout its lifespan.

When compared to other types of air compressors, such as reciprocating compressors or centrifugal compressors, twin screw compressors generally perform better in terms of energy efficiency. Reciprocating compressors, while effective in certain applications, tend to have higher energy consumption due to their intermittent operation, where air is compressed in discrete strokes rather than continuously. This results in more wear and tear on the system, requiring more energy to operate.

Centrifugal compressors, on the other hand, are often used for high-volume applications and can achieve high efficiency at large capacities. However, they may not be as efficient at lower loads, and their operational complexity can result in higher energy costs in some cases. Twin screw air compressors, particularly those with VSDs, offer a good balance of energy efficiency, ease of maintenance, and versatility across a wide range of applications.

Ongoing advancements in compressor technology continue to improve the energy efficiency of twin screw air compressors. Newer models incorporate advanced electronic controls, improved rotor designs, and better sealing systems, all of which contribute to reducing energy consumption. The use of advanced monitoring and control systems can further optimize the operation of the compressor, allowing it to adjust dynamically to changing air demand and environmental conditions.

Many industries have successfully implemented twin screw air compressors with VSDs to reduce their energy costs. For example, in manufacturing facilities with fluctuating air demands, the use of variable speed drives has resulted in significant energy savings. In some cases, companies have reported reductions in energy consumption of up to 30% or more by switching from traditional compressors to energy-efficient twin screw models with VSDs. These energy savings not only lower operating costs but also contribute to a more sustainable operation, reducing the overall environmental impact of the facility.

The energy efficiency of twin screw air compressors can be optimized by selecting the right compressor size, utilizing variable speed drives, and maintaining optimal operational conditions. Regular maintenance and performance monitoring are essential to ensure that the compressor continues to operate efficiently throughout its lifespan. While twin screw compressors are generally more energy-efficient than other compressor types, their efficiency can vary depending on factors such as load profile and application requirements. By taking these factors into account and investing in the latest compressor technologies, companies can reduce energy consumption, lower operational costs, and achieve more sustainable practices in their compressed air systems.

Is it common for micro-oil twin-screw air compressors to experience performance degradation after prolonged operation at full load?

Does the micro-oil twin screw air compressor incorporate effective vibration damping and noise reduction designs?

Your email address will not be published. Required fields are marked *

A dedicated after-sales service department is established, consisting of a professional sales team and skilled technical engineers. They are committed to providing year-round support, traveling to customer locations to deliver prompt and high-quality service.

Tel:86-0570-7221666

E-mail:[email protected]

Add: No.2 Qiming Road, Zhejiang Longyou Economic Development Zone, Mohuan Township, Longyou County, Quzhou City, Zhejiang Province, China