Does the 20HP Micro-Oil Twin Screw Single Stage Compressor Support Both Fixed Frequency and Variable Frequency Configurations?

Overview of Frequency Configuration Options for Industrial Compressors

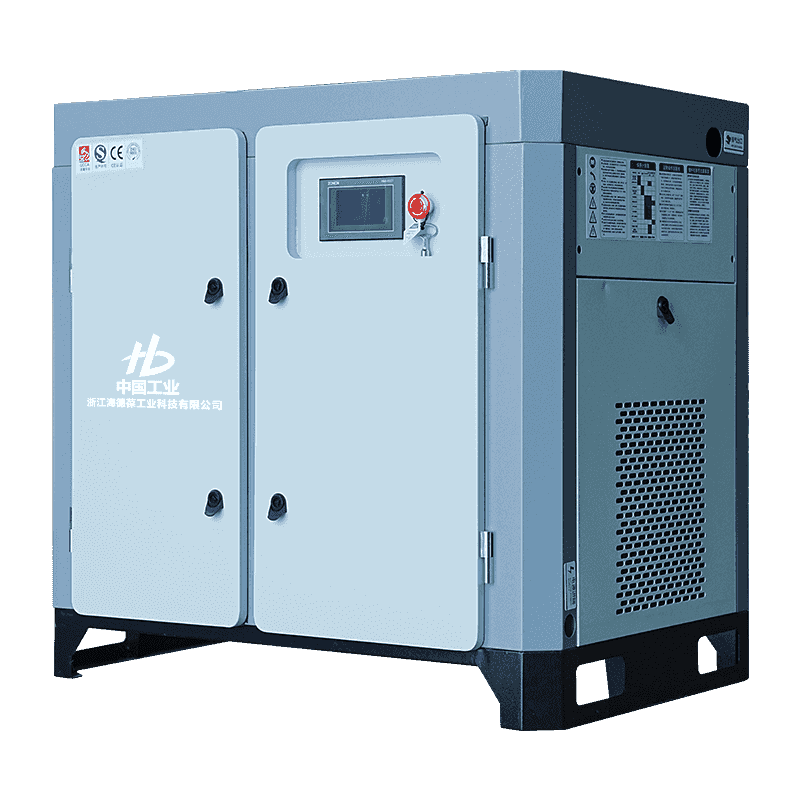

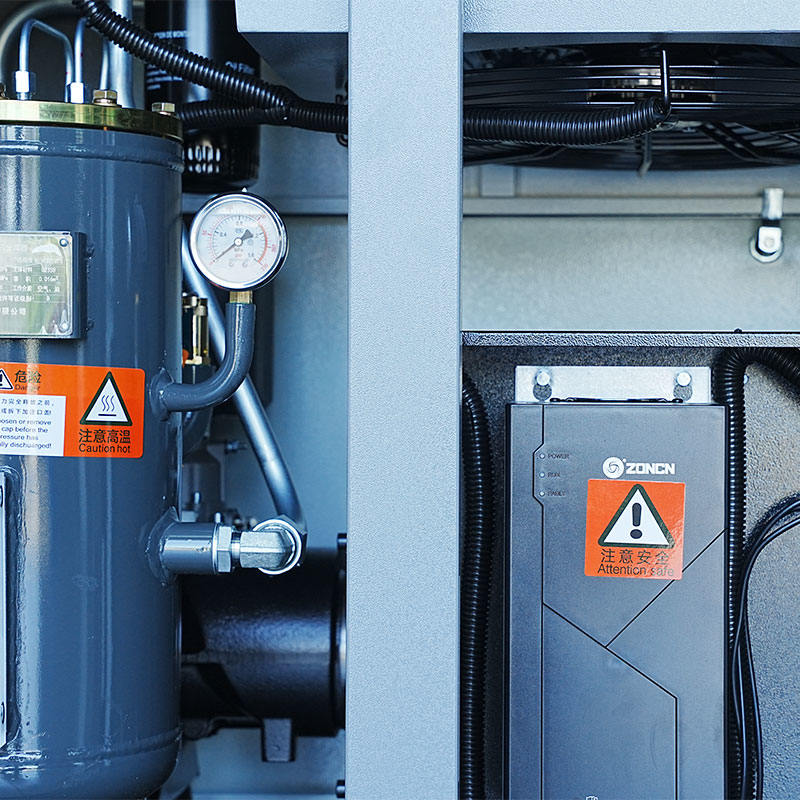

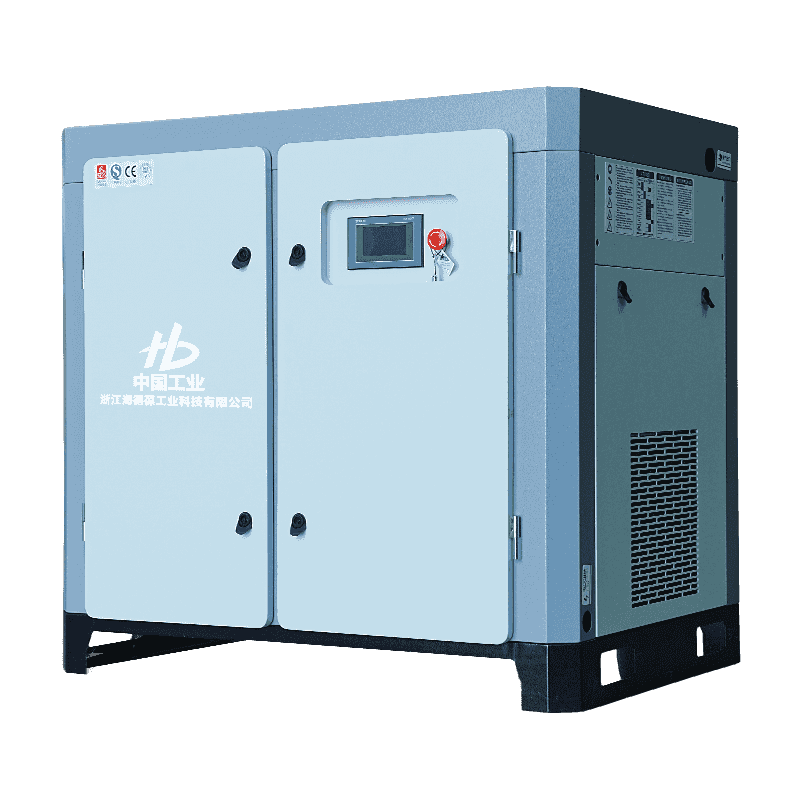

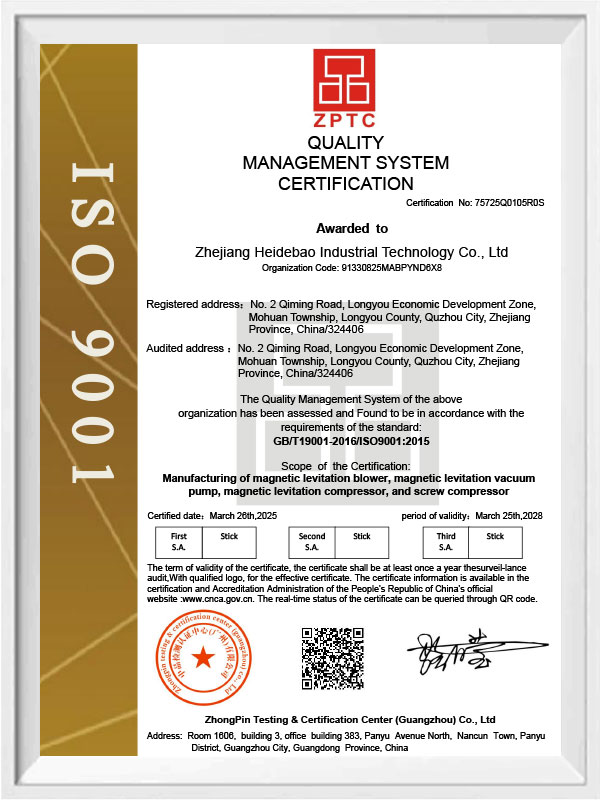

In modern industrial environments, compressed air systems must adapt to diverse operating conditions, energy consumption goals and airflow demand patterns. Frequency configuration—whether fixed or variable—directly influences how efficiently a compressor manages these requirements. The 20HP micro-oil twin screw single stage compressor produced by Zhejiang Haidebao Industrial Technology Co., Ltd., located in Quzhou City, Zhejiang Province, is designed to meet the needs of industries that prioritize stability, energy awareness and stable air quality. The compressor integrates a direct-driven system, micro-oil lubrication, and advanced acoustic control technologies, all of which influence how frequency configurations can be applied. Understanding its potential for fixed and variable frequency setups helps users select suitable configurations for specific industrial tasks or performance expectations.

Fixed Frequency Configuration and Its Operational Characteristics

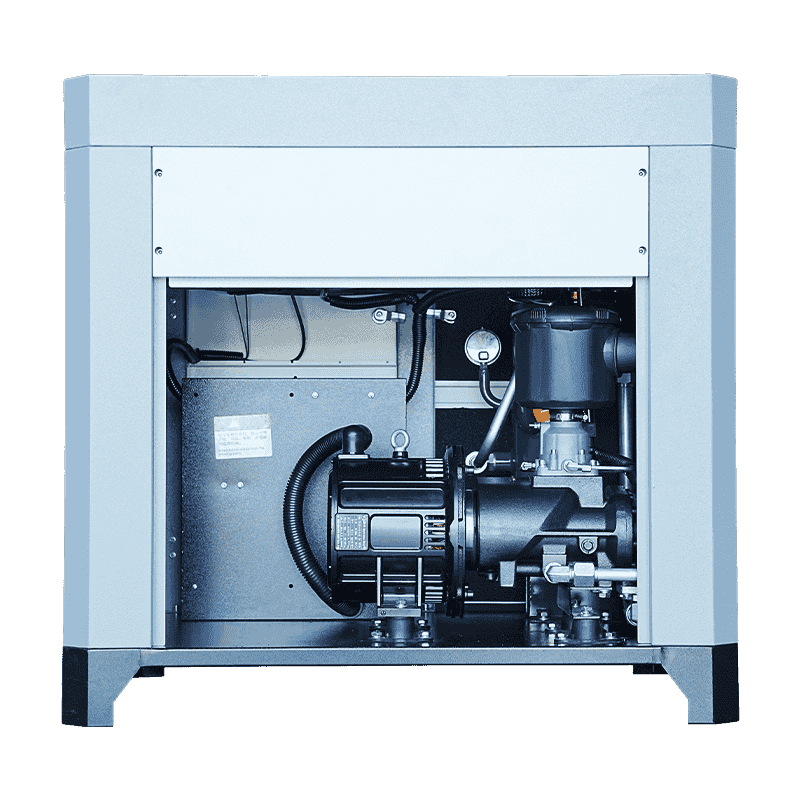

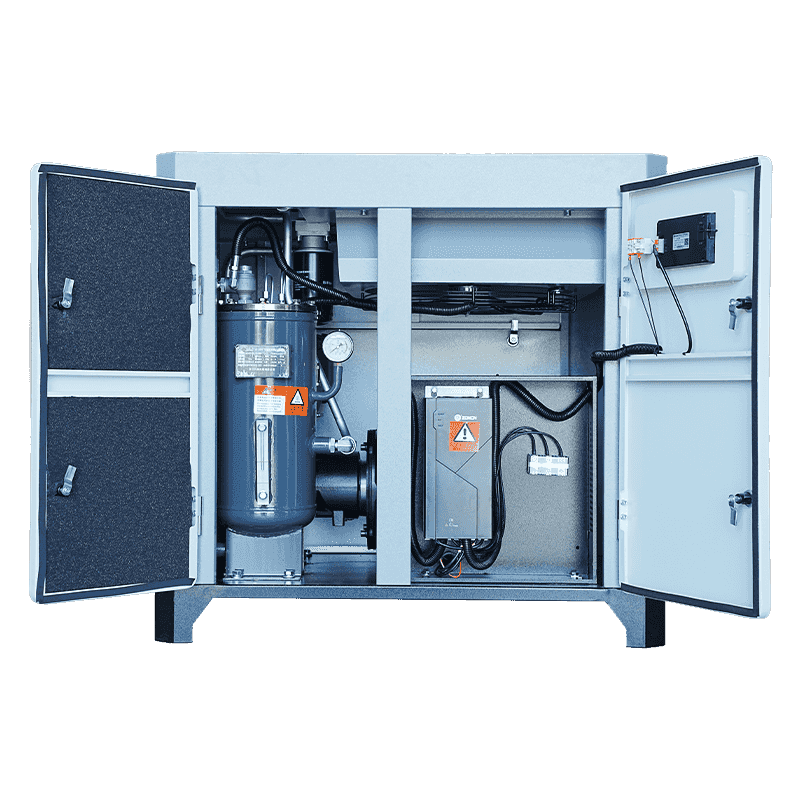

A fixed frequency configuration allows the 20HP micro-oil twin screw single-stage compressor to operate at a constant motor speed. When equipped with this configuration, the compressor runs steadily, providing a continuous airflow output level determined by the rated operating speed. Zhejiang Haidebao Industrial Technology Co., Ltd. implements a 1:1 direct connection design between the motor and the airend, which means that fixed frequency operation maintains a direct and predictable energy-to-output relationship. The oil-cooled permanent magnet synchronous motor contributes to this stability because it produces consistent torque without requiring excitation current. This configuration is suitable for industrial applications with stable and unchanging airflow demand, such as certain production lines or controlled processing environments. The micro-oil lubrication system and noise-reduction design further support continuous operation without abrupt fluctuations.

Variable Frequency Configuration and Its Fu

| Fixed Frequency Feature |

Description |

Application Scenario |

| Constant motor speed |

Outputs air at a stable rate |

Processes with steady demand |

| Direct drive design |

Improves torque transfer consistency |

Continuous production lines |

| Oil-cooled PM motor |

Provides stable thermal and mechanical behavior |

Long-duration operations |

nctional Advantages

Variable frequency control allows the motor to dynamically adjust its speed according to real-time air demand. For the 20HP micro-oil twin screw single stage compressor, this configuration enhances energy flexibility because the compressor no longer needs to operate at a constant load. Instead, the frequency inverter determines the optimal motor speed required to meet airflow demand while reducing unnecessary energy consumption. This configuration is especially advantageous in facilities with fluctuating production schedules, diverse equipment loads or intermittent air usage patterns. When paired with Zhejiang Haidebao Industrial Technology Co., Ltd.’s oil-cooled permanent magnet synchronous motor, the variable frequency system ensures smooth speed transitions and controlled temperature behavior. The compressor’s multi-level noise management further supports variable frequency operation by preventing abrupt sound changes during speed adjustments.

| Variable Frequency Benefit |

Description |

Industrial Advantage |

| Adjustable motor speed |

Matches airflow demand |

Energy savings during low demand |

| Smoother load transitions |

Reduces mechanical stress |

Longer equipment service life |

| Noise control compatibility |

Maintains stable acoustic levels |

Improved working environment |

Compatibility of the Compressor With Both Frequency Modes

The design of the 20HP micro-oil twin screw single stage compressor supports flexibility in configuration. Zhejiang Haidebao Industrial Technology Co., Ltd. manufactures the compressor with a structural and electrical architecture that accommodates both fixed frequency and variable frequency settings. The permanent magnet synchronous motor provides consistent performance in either mode due to its inherent characteristics of stable torque output and low temperature rise. Additionally, the 1:1 direct connection between the motor and the screw airend allows the system to transition efficiently between fixed and variable frequency versions during production or installation. Oil circuit pathways, cooling systems designed for reliable heat dissipation and the micro-oil lubrication setup remain effective regardless of frequency selection. This enables users to install the compressor in environments where frequency choice depends on operational planning, energy budgeting or workflow patterns.

Environmental and Operational Conditions That Influence Frequency Selection

The compressor’s design integrates multiple environmental adaptability features, including a cooling system capable of handling various thermal loads and noise control technologies that allow it to operate comfortably in noise-sensitive environments. When selecting between fixed and variable frequency configurations, users must consider their ambient environment, production cycle variations and energy optimization goals. In facilities with persistent high air demand, a fixed frequency model provides reliable operation without requiring inverter-based adjustments. In contrast, facilities with fluctuating air needs—common in packaging, assembly or laboratory-style operations—benefit from variable frequency systems that reduce power consumption during low-demand cycles. Because the compressor produces cleaner and more controlled airflow through micro-oil lubrication and purification components, both configurations support industries requiring high-quality gas sources, such as food processing or pharmaceutical manufacturing.

Comparative Analysis of Fixed and Variable Frequency Configurations

Although both configurations are compatible with the 20HP micro-oil twin screw single stage compressor, their energy behavior and system responses differ in predictable ways. Fixed frequency systems emphasize stability and predictable airflow, while variable frequency configurations promote cost management through energy adaptability. Zhejiang Haidebao Industrial Technology Co., Ltd. enables both paths by implementing a balanced combination of mechanical precision, optimized lubrication, direct-driven architecture and motor technology. Users can determine the most suitable configuration by evaluating their operational consistency, energy targets and required airflow patterns.

English

English Español

Español عربى

عربى