What Are the Noise and Vibration Levels of a 100HP Micro-Oil Twin Screw Two-Stage Compressor During Long-Term Operation?

Influence of Structural Design on Noise and Vibration Control

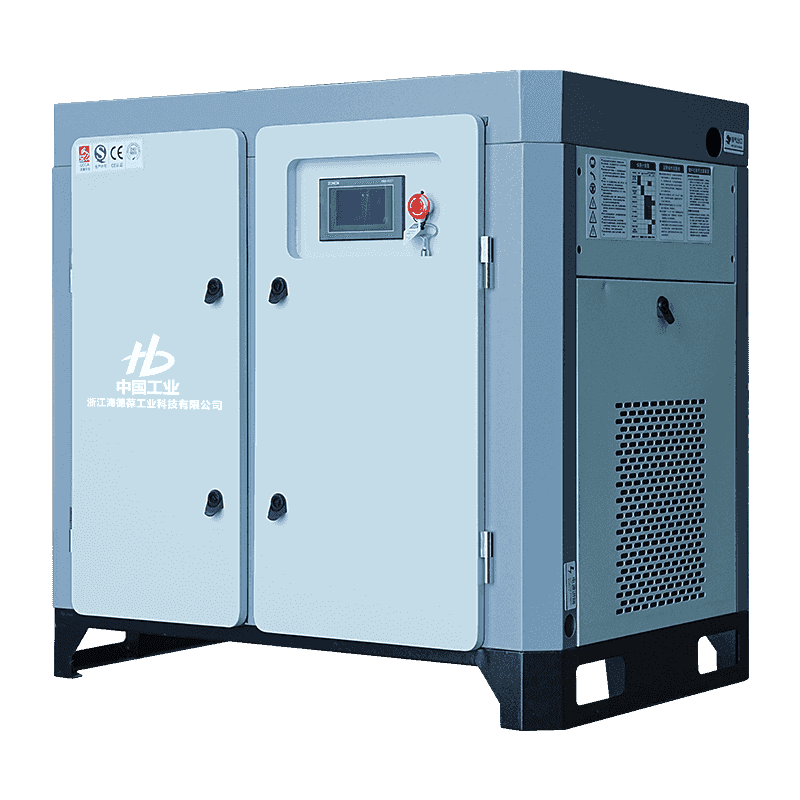

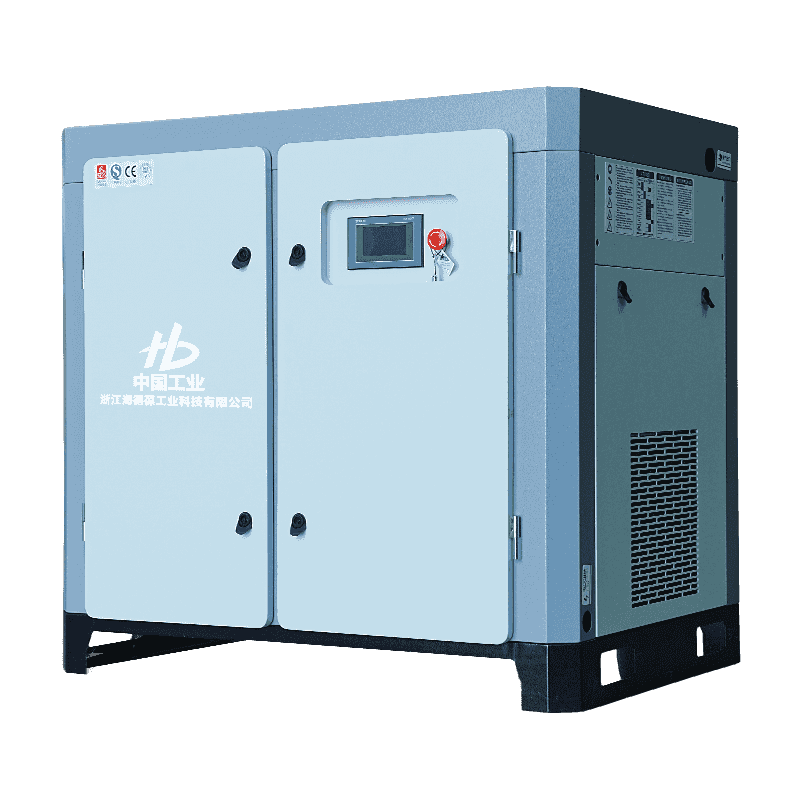

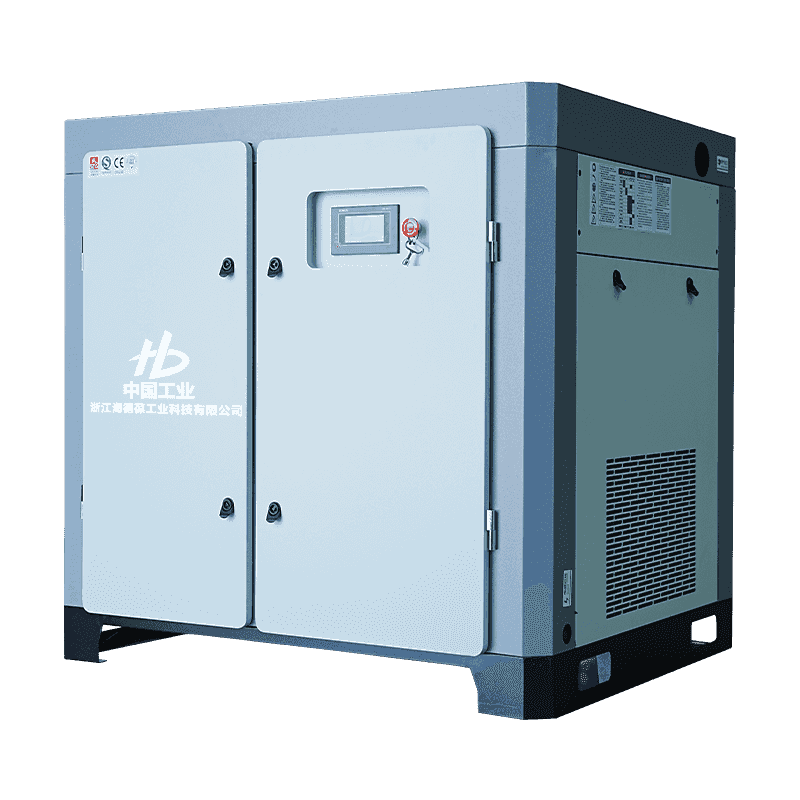

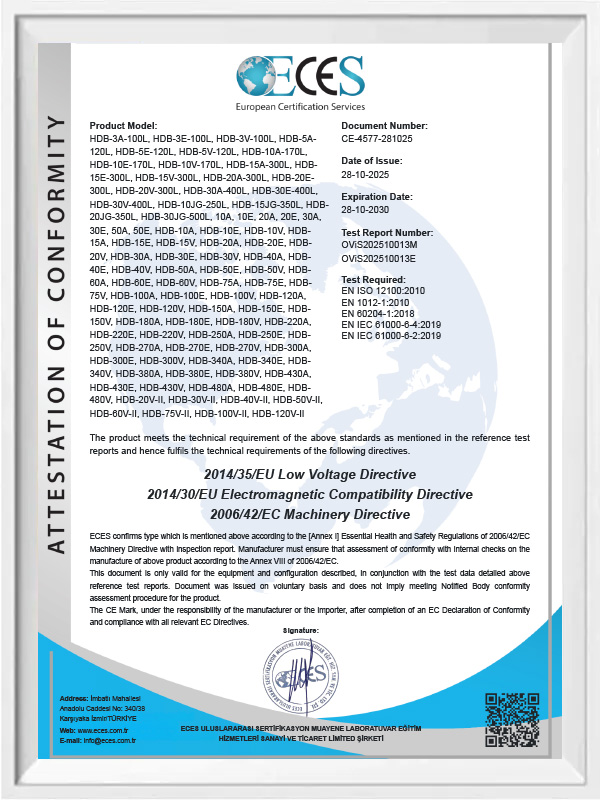

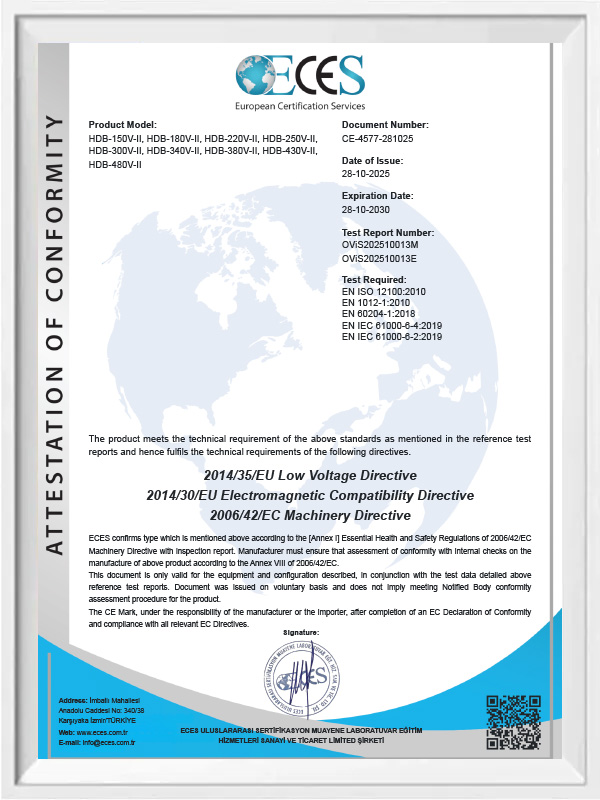

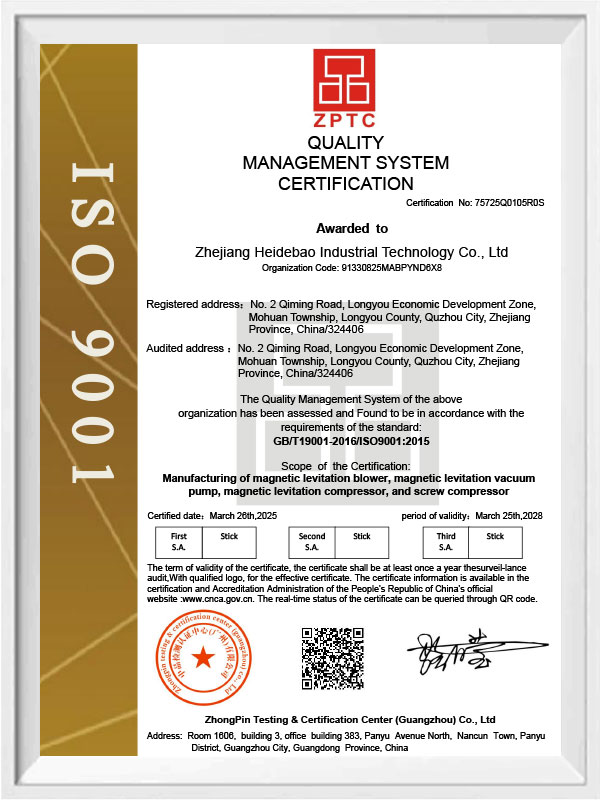

The structural design of the 100HP micro-oil twin screw two-stage compressor greatly influences its noise and vibration characteristics during long-term operation. Manufactured by Zhejiang Haidebao Industrial Technology Co., Ltd., located in Quzhou City, Zhejiang Province, the compressor integrates an innovative main engine design with a precision-built compressor head and a patented rotor profile. These design strategies help maintain stable mechanical alignment and reduce unnecessary movement inside the unit. By optimizing the rotor shape and airflow channels, internal air impact is minimized, which helps control acoustic output. The careful selection of high-standard components ensures smoother mechanical operation, contributing to stable running conditions. As a result, structural integrity reduces the generation of mechanical and aerodynamic noise during extended use.

Effect of 1:1 Direct Connection on Vibration Reduction

The 100HP micro-oil twin screw two-stage compressor employs a 1:1 direct connection configuration between the main engine and the motor, which significantly influences vibration control. Unlike belt-driven systems, which may introduce tension imbalance, belt wear, or rotational inconsistencies, the direct connection eliminates these potential vibration sources. By aligning the motor and the compression unit directly, transmission loss is minimized and rotational stability is enhanced. This helps the compressor maintain a consistent operational rhythm even under high load. Long-term use often exposes equipment to mechanical fatigue, but the simplified transmission structure reduces the number of components subject to wear, decreasing vibration fluctuations throughout the service life of the compressor.

Role of Oil-Cooled Permanent Magnet Synchronous Motor in Noise Suppression

The compressor is equipped with an oil-cooled permanent magnet synchronous motor, which contributes to stable noise control. Permanent magnets with low temperature rise protection ensure that thermal expansion is kept within a manageable range, avoiding excessive friction or mechanical stress that could increase noise. The cooling system maintains the motor at a steady temperature, preventing abrupt operational changes that might lead to noise spikes. Since the motor does not require excitation current, its operation is smooth and consistent, which enhances acoustic stability. The controlled motor speed also minimizes tonal noise, helping maintain a predictable noise level even during prolonged operation.

Two-Stage Compression and Its Acoustic Characteristics

Two-stage compression affects noise levels by distributing the compression workload across two separate stages. For the 100HP micro-oil twin screw compressor, the gas is compressed gradually rather than in a single high-pressure step, reducing the intensity of internal pressure fluctuations. Lower fluctuation levels result in a smoother compression process and less generation of noise caused by abrupt pressure changes. The rotor profile, optimized to reduce leakage and improve sealing efficiency, also influences internal acoustic behavior. With reduced turbulence and stable airflow patterns, the compressor produces lower aerodynamic noise. This balanced compression cycle supports consistent sound profiles during long-term operation, beneficial for industrial settings where continuous equipment activity is expected.

Noise Distribution Under Continuous Industrial Use

Noise distribution of the 100HP model changes depending on the operating environment, ventilation conditions, and load requirements. During continuous industrial operation—such as in chemical, pharmaceutical, or plastic processing facilities—the compressor maintains relatively stable sound output due to its synchronized mechanical operation. Installation layout also plays a role; placing the unit on a level foundation helps avoid secondary vibration that can amplify noise. The overall design minimizes sharp tonal elements, leading to noise that is more uniform and less disruptive. Over long periods, consistency becomes a major advantage, as stable noise levels support safer workplace acoustic conditions.

| Noise and Vibration Factor |

100HP Micro-Oil Twin Screw Two-Stage Compressor |

Typical Industrial Compressor |

| Motor Transmission Method |

1:1 direct connection reduces vibration |

Belt drive may cause additional vibration |

| Internal Pressure Stability |

Two-stage compression lowers pressure fluctuation |

Single-stage may produce higher fluctuation |

| Thermal Control |

Oil-cooled permanent magnet motor stabilizes heat |

Higher operating temperature increases noise |

| Long-Term Vibration Behavior |

Lower vibration due to controlled internal movement |

Vibration may increase as components wear |

Impact of Material Selection and Component Precision on Vibration

Zhejiang Haidebao Industrial Technology Co., Ltd. uses high-standard materials for the compressor’s internal and external components, and this directly affects vibration performance. The precision machining of the compressor head and rotor enables consistent rotor clearance and smooth rotation. Reduced deviation in rotor alignment helps maintain equilibrium within the compression chamber. The robust casing structure is designed to absorb operational vibration rather than amplify it. Over long-term operation, precise materials and solid construction reduce structural resonance, ensuring predictable vibration levels and extending the lifespan of the machine’s internal bearings and moving parts.

Noise Behavior Under High Load and Continuous Duty Cycles

In high-demand industrial applications, compressors often operate under heavy load conditions for extended durations. The 100HP micro-oil twin screw two-stage compressor maintains stable noise levels during these conditions due to consistent internal dynamics and efficient heat dissipation. When gas demand increases, the two-stage rotor system handles the workload without rapid pressure spikes, helping avoid sudden noise increases. The steady temperature control of the permanent magnet motor also reduces thermal-related noise changes. This stability ensures smoother acoustic behavior in production facilities where equipment operates continuously around the clock.

Vibration Isolation and Foundation Requirements

Although the compressor features low vibration characteristics by design, installation on a reinforced and properly leveled foundation further supports long-term vibration control. Proper alignment during installation helps maintain balance between the motor and the compression unit. Over time, external factors such as floor movement or equipment shifts can affect operational stability. Regular verification of installation alignment helps prevent secondary vibration, particularly in environments with multiple heavy machines operating simultaneously. When supported by a suitable foundation, the compressor maintains stable vibration levels and operates with reduced mechanical stress, enhancing service life and operational reliability.

Long-Term Acoustic and Vibration Stability in Industrial Applications

During extended operation, the 100HP micro-oil twin screw two-stage compressor demonstrates stable acoustic and vibration performance due to its integrated design, advanced motor technology, and optimized compression mechanism. Its structural balance ensures that noise does not increase significantly over time, while internal lubrication and thermal control maintain consistent dynamic behavior. In industries where continuous gas supply is essential, such as chemical manufacturing, food processing, and pharmaceutical production, the predictable noise and vibration characteristics contribute to safer working environments. This long-term stability reflects the engineering approach of Zhejiang Haidebao Industrial Technology Co., Ltd., which focuses on creating durable and efficient equipment capable of supporting demanding industrial operations.

English

English Español

Español عربى

عربى