What Is the Pressure Stability Range of the Frequency Converter Control for a 120HP Micro-Oil Twin Screw Two-Stage Compressor?

Influence of the High-Efficiency Frequency Converter on Pressure Stability

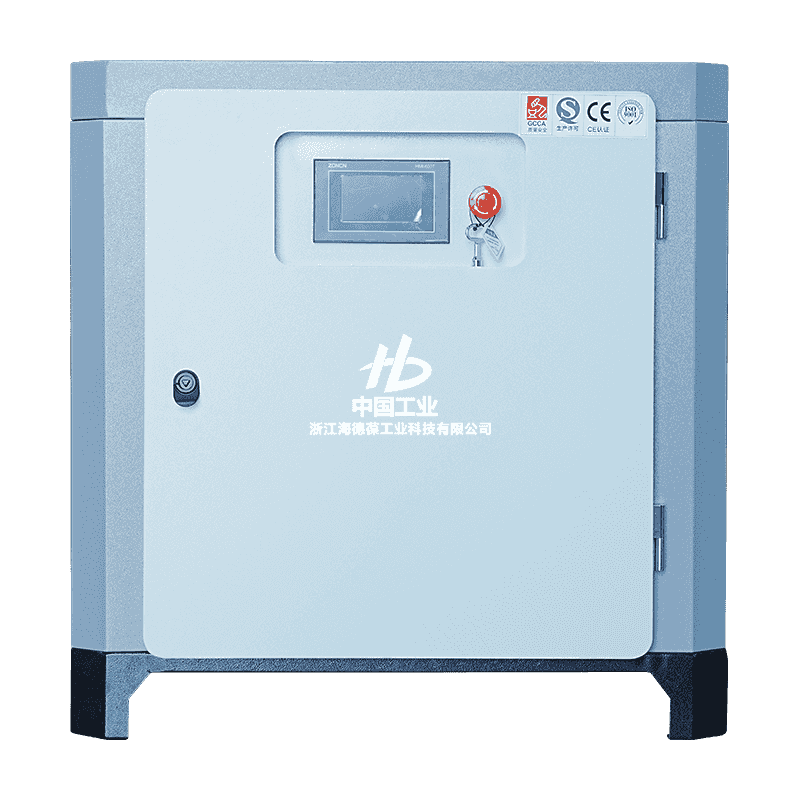

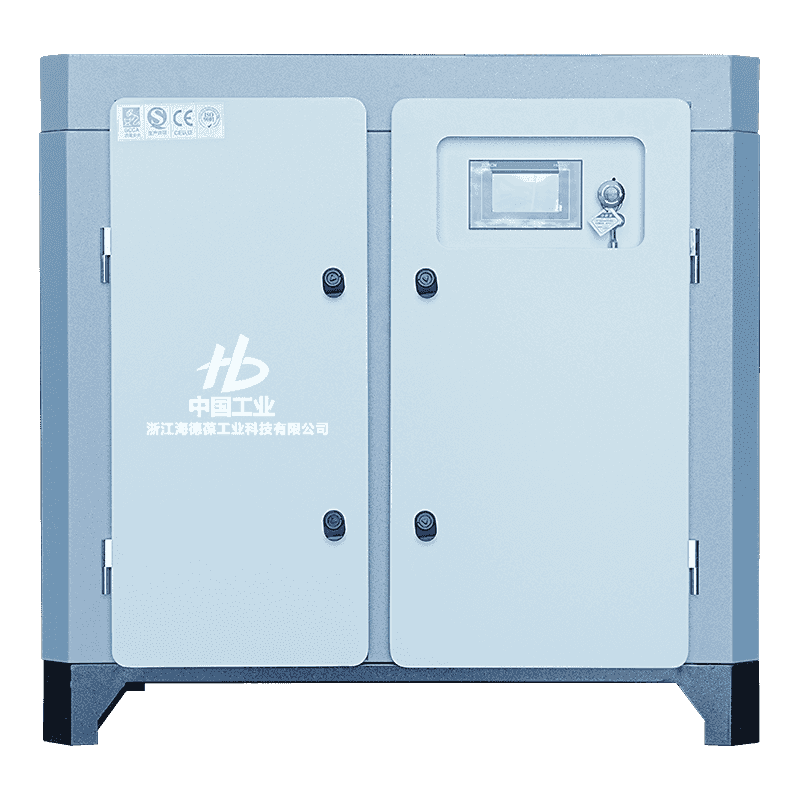

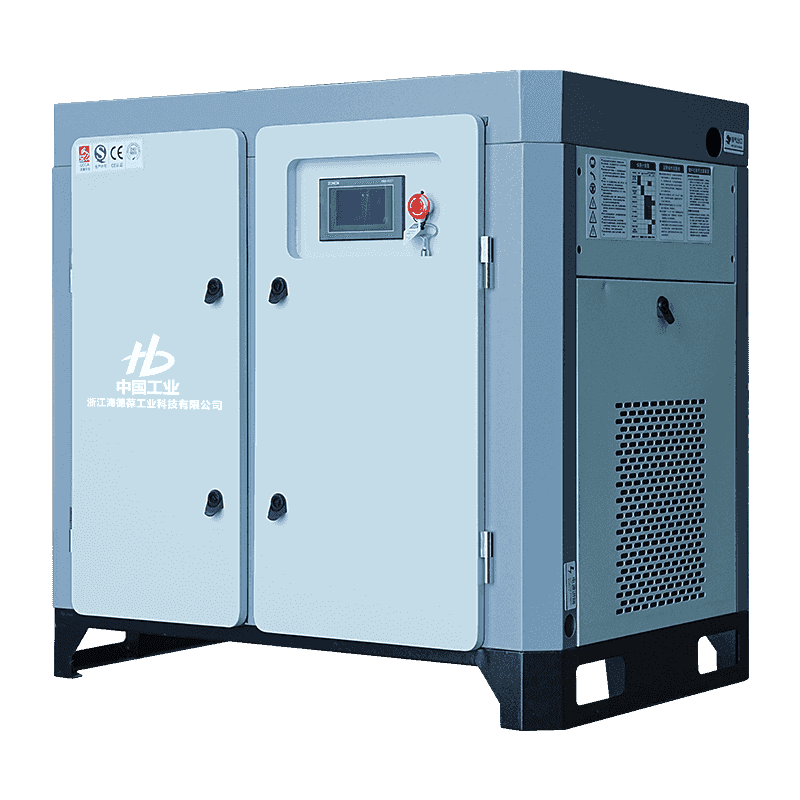

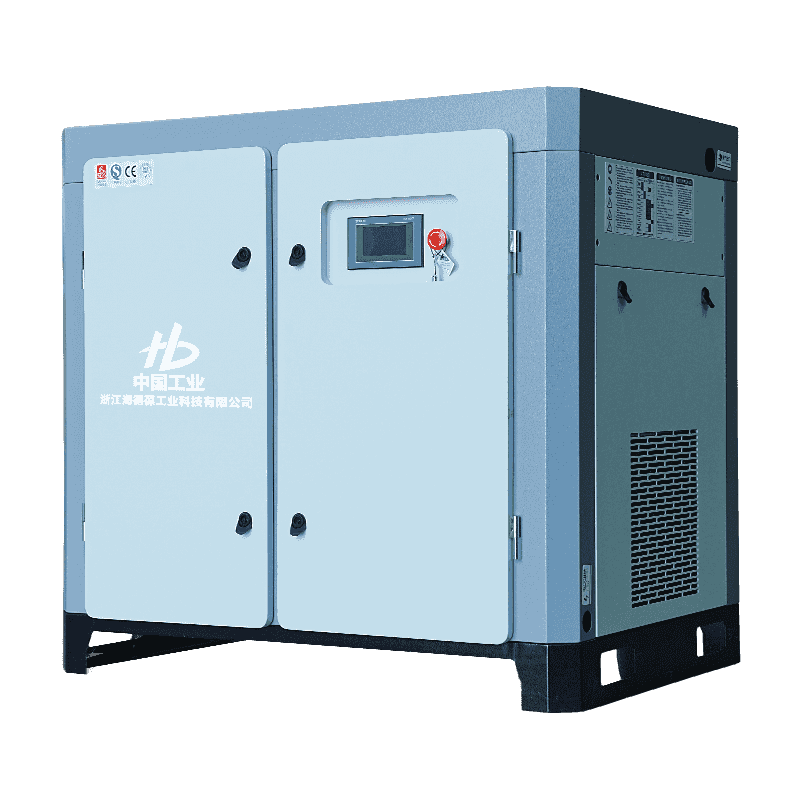

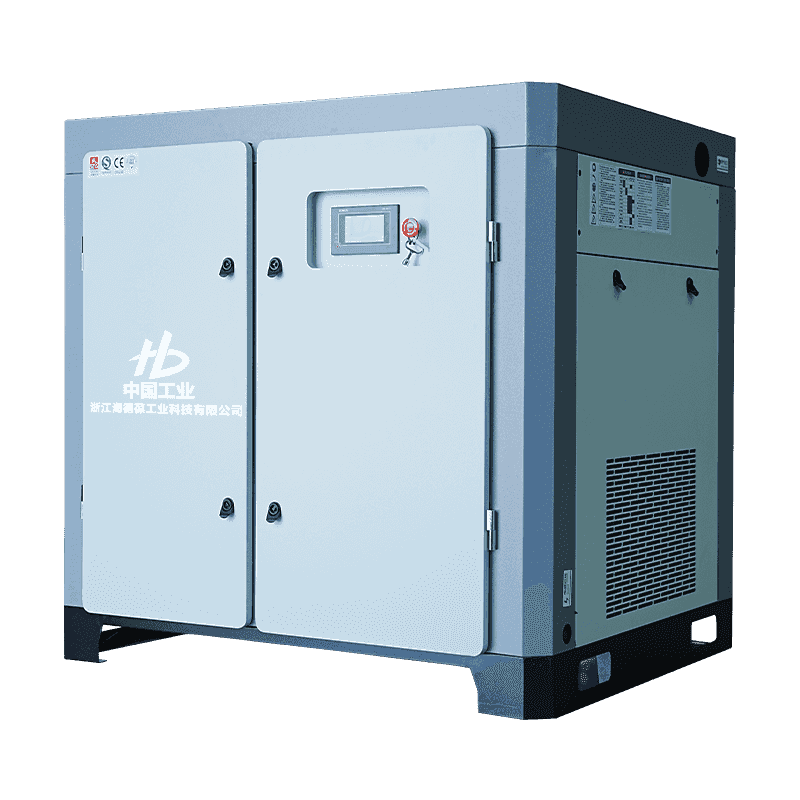

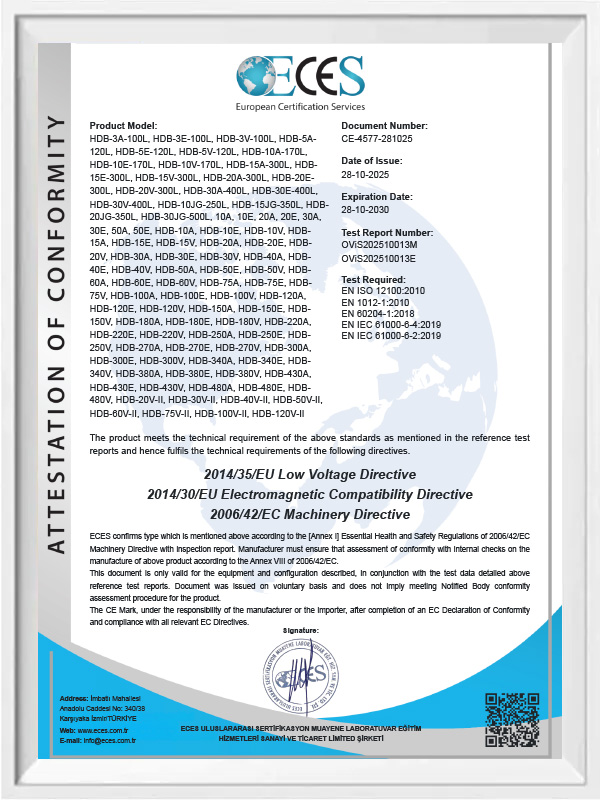

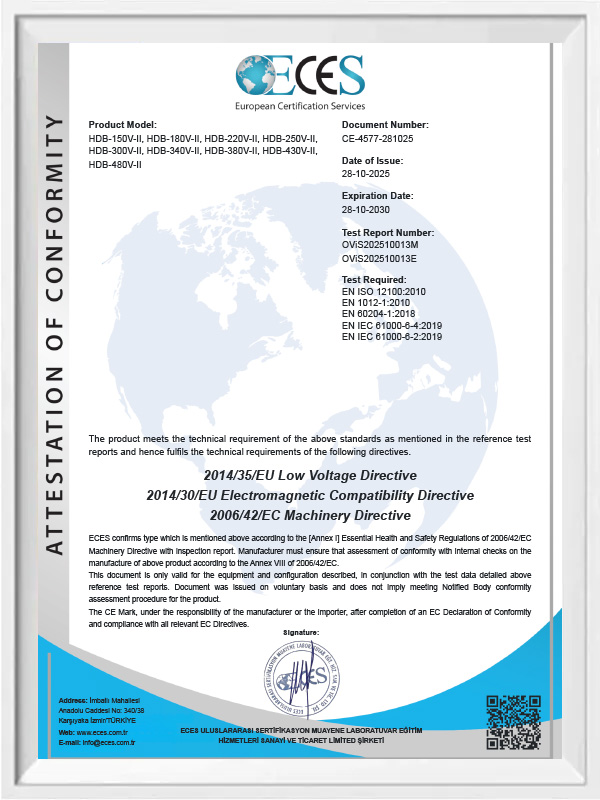

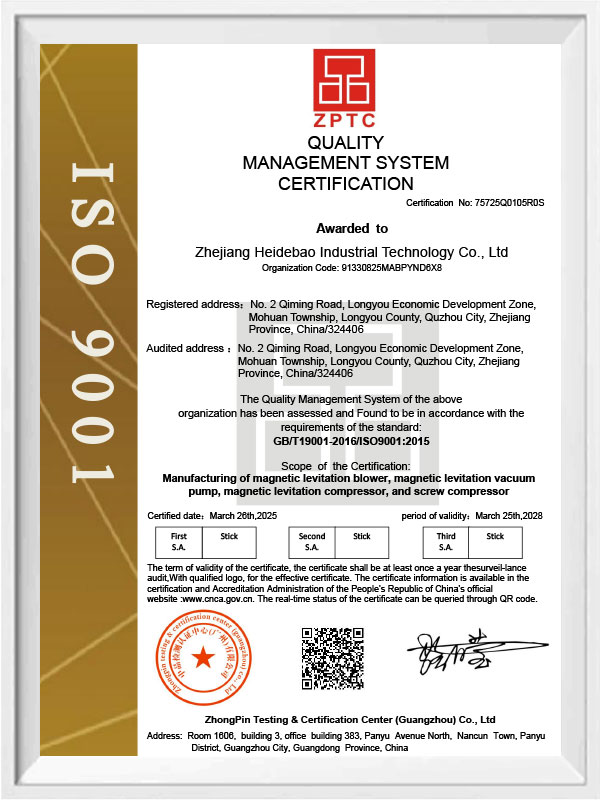

The pressure stability of the 120HP micro-oil twin screw two-stage compressor is closely related to the performance of its high-efficiency frequency converter, which is specifically engineered to deliver a wide speed regulation range and high torque at low rotational speeds. Manufactured by Zhejiang Haidebao Industrial Technology Co., Ltd., the compressor integrates a 90 kW permanent magnet synchronous motor with an advanced vector control inverter that manages dynamic pressure fluctuations during varying load conditions. By adjusting motor speed in real time based on system pressure feedback, the inverter maintains air pressure within a narrow and controlled range. This capability is essential for applications requiring consistent supply stability, such as chemical production, pharmaceutical processing, and precision manufacturing environments.

Role of Current Vector Control in Maintaining Pressure Consistency

The frequency converter utilizes current vector control technology, which enhances pressure stability by improving the accuracy of motor torque output. This control method allows the inverter to respond quickly to pressure deviations, ensuring that changes in demand do not introduce substantial pressure swings within the system. When gas consumption increases suddenly, the inverter accelerates the motor instantly to restore pressure balance. Conversely, when consumption drops, the motor speed reduces in a controlled manner to avoid excessive system pressure. This dynamic response helps maintain a stable pressure band that is critical for two-stage compression systems where discharge pressure can be affected by temperature, load, and airflow fluctuations.

Working Pressure Range and Stability Characteristics

The 120HP micro-oil twin screw two-stage compressor provides three primary working pressure levels—8 bar, 10 bar, and 13 bar—delivering air outputs of 20.2 m³/min, 16.0 m³/min, and 12.1 m³/min respectively. While these represent the rated performance levels, the frequency converter enables fine pressure adjustment within these ranges to match real-time operational needs. The inverter maintains pressure within a narrow deviation range, typically around ±0.1 to ±0.2 bar under stable load conditions. This tight control is achieved through precise motor modulation and continuous monitoring of discharge pressure. The stable range supports energy efficiency and helps reduce mechanical stress on the compressor, extending component life.

Effect of Wide Voltage Input Range on Pressure Stability

The wide voltage input range of the frequency converter allows the compressor to maintain pressure stability even when power supply conditions fluctuate. Voltage variations can affect torque output and motor speed if not properly compensated. The inverter's wide input tolerance ensures that it can regulate speed effectively even under low or unstable voltage conditions, maintaining consistent pressure delivery. The added derating margin improves reliability, preventing performance drops during long-term operation. This feature is especially beneficial in industrial environments where voltage instability is common due to multiple large machines operating simultaneously. The inverter’s adaptability supports uninterrupted and stable pressure performance, reducing the overall risk of pressure-related operational issues.

Impact of Permanent Magnet Synchronous Motor on Pressure Control

The permanent magnet synchronous motor contributes significantly to maintaining a steady pressure range, as it operates without excitation current, resulting in smooth torque output and stable rotational characteristics. This motor type offers high operational consistency, which directly enhances the precision of pressure regulation by minimizing torque ripple and rotational instability. The low starting current also reduces initial impact on the power grid, ensuring that pressure parameters remain controlled during startup and abrupt load shifts. Additionally, the motor’s reduced heat generation aids the frequency converter in maintaining a consistent speed-efficiency relationship, supporting narrow pressure fluctuation limits.

Pressure Stability During Load Variations

Load variations pose one of the primary challenges for pressure regulation in compressed air systems. The frequency converter in the 120HP compressor continuously adjusts motor speed to accommodate sudden increases or decreases in compressed air demand. Under rapid load increases, the inverter raises speed promptly, controlling pressure drop and maintaining supply consistency. During load reductions, the inverter reduces motor output to avoid unnecessary pressure buildup. This real-time modulation helps maintain a predictable pressure range. Even under highly dynamic conditions, pressure deviations remain controlled due to the inverter’s fast response time and high motor torque at low speeds.

| Operating Parameter |

120HP Micro-Oil Twin Screw Two-Stage Compressor |

Impact on Pressure Stability |

| Rated Pressure Levels |

8 bar, 10 bar, 13 bar |

Supports multiple stable working bands |

| Pressure Deviation |

±0.1–0.2 bar (typical) |

Enables consistent operation under load changes |

| Frequency Converter Type |

High-performance vector control inverter |

Improves dynamic response and accuracy |

| Voltage Input Range |

Wide tolerance with derating margin |

Protects pressure stability under voltage fluctuations |

| Motor Characteristics |

Permanent magnet synchronous motor |

Ensures smooth torque output for stable pressure |

Long-Term Pressure Stability in Continuous Use

In long-term industrial operation, pressure stability becomes increasingly important for maintaining equipment reliability and supporting continuous workflow. The 120HP micro-oil twin screw two-stage compressor ensures long-term pressure consistency through its integrated control system and advanced inverter regulation. The efficiency and power factor of the permanent magnet synchronous motor remain nearly constant over extended operation, ensuring that pressure control remains predictable. The inverter’s thermal management system reduces the risk of performance deterioration over time, which helps prevent gradual widening of the pressure fluctuation range. This long-term consistency supports industrial applications where uninterrupted production and uniform compressed air quality are essential.

Pressure Regulation Performance Under Extreme Conditions

The compressor’s inverter control system is built to maintain pressure stability even under demanding conditions such as high ambient temperatures or intensive usage cycles. The system’s derating margin ensures that the inverter can operate safely without compromising pressure accuracy, even when ambient temperatures rise. Additionally, the motor’s low temperature rise protection helps maintain thermal equilibrium, reducing the likelihood of pressure drift caused by overheating. In applications involving rapid cycling or highly variable air demand, the inverter’s quick response capabilities help sustain pressure stability, preventing issues such as equipment malfunction or production inconsistency due to pressure deviation.

Overall Pressure Stability Range Supported by the Inverter

Considering its wide speed adjustment capability, high torque availability, and real-time vector control, the frequency converter of the 120HP micro-oil twin screw two-stage compressor maintains pressure stability within a narrow, efficient, and predictable range throughout operation. Whether the system is functioning at 8 bar, 10 bar, or 13 bar, the inverter ensures that the compressor maintains a steady output with minimal deviation. In practical industrial environments, users can expect consistent pressure delivery even during fluctuating load demands, voltage instability, or long operational cycles. This predictable pressure stability reflects the engineering approach of Zhejiang Haidebao Industrial Technology Co., Ltd., supporting reliable, efficient, and stable air supply for various industrial applications.

English

English Español

Español عربى

عربى