Product Consultation

Your email address will not be published. Required fields are marked *

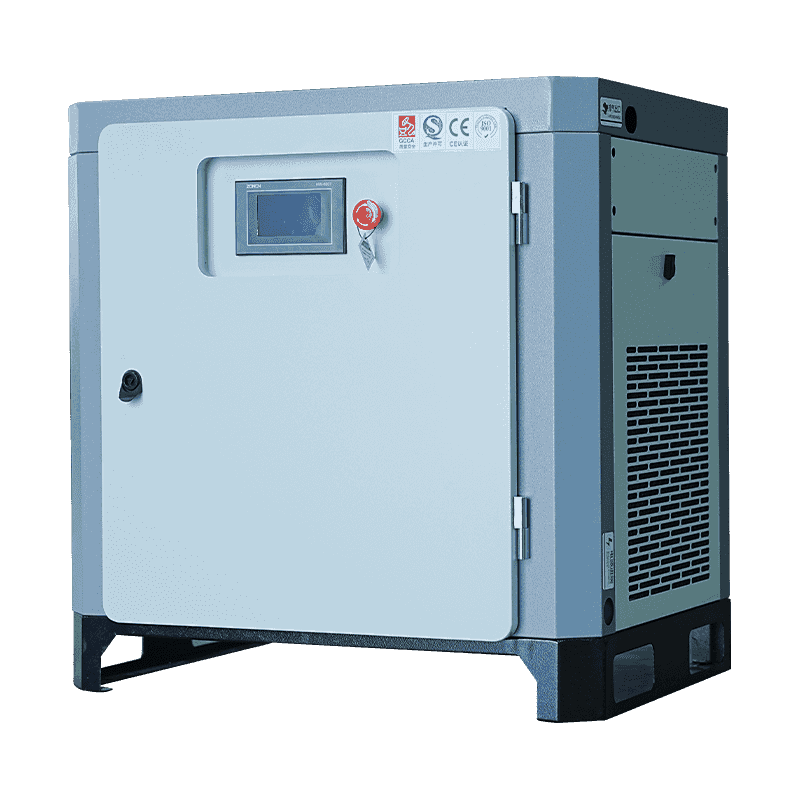

Micro-oil twin screw single-stage compressors are commonly used in industrial applications that require compressed air or gas. These compressors operate by utilizing two intermeshing screws to compress the air, with oil injected to lubricate the moving parts and help seal the compression chambers. The performance of these compressors is largely determined by various factors, including the quality of the materials, the precision of the mechanical components, and, importantly, the operating conditions under which the compressor is running. Understanding how these compressors perform under different operating conditions is crucial for ensuring their stability, reliability, and longevity.

The micro-oil twin screw single-stage compressor uses two intermeshing rotors that rotate in opposite directions. As the rotors rotate, air is drawn into the compression chamber and progressively compressed as the screws mesh together. Oil is injected into the compression chamber to serve several purposes: lubricating the rotors, cooling the compression process, and improving sealing between the rotors and the casing. The oil helps maintain stable temperatures during compression and minimizes wear on the mechanical components, which is critical for long-term reliability. These compressors are often used in environments where precision and continuous operation are required, such as in manufacturing, automotive, and chemical industries. The stability of the compressor's performance is influenced by how effectively it can handle fluctuations in load, temperature, and other environmental variables.

The performance of a micro-oil twin screw single-stage compressor can vary significantly depending on the load placed on it during operation. In most industrial settings, the compressor is expected to operate under varying load conditions, where the demand for compressed air or gas fluctuates. Load variations can occur due to changes in the production line’s requirements or environmental conditions. Under low-load conditions, the compressor may experience reduced efficiency as the energy input does not match the reduced demand, leading to energy losses. Conversely, under high-load conditions, the compressor may work at maximum capacity, which could lead to increased wear and tear on the mechanical components and the oil system. The oil temperature may also increase under heavy load, which could negatively affect lubrication and sealing performance. As the load varies, the system may also experience changes in the discharge pressure, leading to fluctuations in performance stability. Efficient compressor control systems and variable speed drives are often used to mitigate the effects of load variations, helping to optimize energy use and maintain stable operation.

Temperature plays a significant role in determining the stability of a micro-oil twin screw single-stage compressor’s performance. The temperature of the intake air, as well as the operating temperature of the compressor, can directly influence its efficiency and durability. When the intake air temperature rises, it can lead to higher discharge temperatures, which in turn may impact the oil's ability to lubricate and cool the compressor. If the oil temperature becomes too high, it can degrade the oil’s performance, leading to reduced lubrication efficiency, increased friction, and potentially accelerated wear on the rotor components. On the other hand, low operating temperatures can lead to poor oil circulation and inadequate lubrication, increasing the risk of mechanical failure. In addition, extreme temperatures can also cause changes in the viscosity of the oil, affecting its ability to create an effective seal between the rotors. To maintain stable performance, it is essential to keep the compressor within a specific temperature range, and this can be achieved through adequate cooling systems, oil management, and monitoring temperature sensors.

The quality of the air or gas being compressed is another important factor that affects the performance stability of a micro-oil twin screw single-stage compressor. Contaminants such as dust, moisture, and impurities can cause operational problems in the compressor. For instance, dust particles may enter the system and cause abrasion on the compressor's rotors and other internal components. Similarly, excessive moisture in the intake air can lead to corrosion of metal parts, degradation of oil quality, and the formation of deposits that could clog the oil system. Moisture can also reduce the efficiency of the compressor by reducing the air’s compressibility, causing the compressor to work harder and consume more energy. Clean, dry, and filtered air is essential for maintaining the performance and lifespan of the compressor. Proper filtration and moisture removal systems, such as air dryers, are often used to address these challenges and ensure that the compressor operates under optimal conditions.

Oil is a critical component in the operation of micro-oil twin screw compressors, and its management directly affects the compressor’s performance stability. The oil serves multiple purposes: lubrication, cooling, and sealing. Over time, the oil may degrade due to thermal and mechanical stress, causing a reduction in its lubricating properties and the potential for increased friction within the compressor. Poor oil quality can also lead to the formation of sludge or carbon deposits, which can block oil passages and affect the overall performance of the compressor. Regular monitoring and maintenance of the oil system, including oil changes and filtration, are necessary to maintain the stability of the compressor. Additionally, selecting the right oil viscosity and type for the operating conditions is crucial for optimal performance. Manufacturers typically provide guidelines on oil selection based on ambient temperatures, load conditions, and the nature of the application. By ensuring proper oil quality and circulation, operators can extend the operational life of the compressor and maintain consistent performance.

Modern micro-oil twin screw compressors often come equipped with advanced control systems that help maintain stable performance under various operating conditions. These systems use sensors to continuously monitor critical parameters such as temperature, pressure, oil quality, and load. By adjusting operational settings in real-time based on feedback from these sensors, the control system can optimize the compressor's performance, preventing overloads, overheating, and other operational issues. For example, variable speed drives (VSD) allow the compressor to adjust its speed in response to changes in load, thereby reducing energy consumption and preventing excessive wear under low-load conditions. Control systems also enable automatic shutdowns or alerts in case of abnormal conditions, helping to prevent damage to the compressor. The integration of automation and control systems is key to maintaining stability and ensuring the compressor operates efficiently over the long term, even under fluctuating environmental conditions.

To ensure long-term stability, regular performance monitoring is essential for micro-oil twin screw single-stage compressors. Over time, wear and tear on the mechanical components, along with changes in operating conditions, can affect the compressor's performance. By using performance data, such as energy consumption, output pressure, and temperature readings, operators can detect early signs of potential issues, such as inefficiency or component failure. Predictive maintenance strategies, which use data analytics to predict when maintenance or part replacement will be required, can help prevent unplanned downtime and extend the lifespan of the compressor. Routine inspections and maintenance, such as checking the alignment of the rotors, cleaning filters, and replacing worn-out seals, are important for ensuring that the compressor continues to perform reliably. A comprehensive maintenance schedule, based on the manufacturer's recommendations and real-time performance data, is crucial for sustaining the compressor’s stability and performance throughout its operational life.

Maintaining consistent performance in micro-oil twin screw single-stage compressors is not without its challenges. One of the primary difficulties is managing the varying environmental and load conditions under which the compressor operates. Fluctuations in temperature, air quality, and load can all affect the compressor's ability to maintain a stable output. Furthermore, the quality of oil and the presence of contaminants in the compressed air can also cause inconsistencies in performance. Even minor changes in operating conditions can have a significant impact on efficiency and reliability. The solution lies in implementing a robust maintenance program, optimizing control systems to handle varying loads, and ensuring the use of high-quality components that can tolerate fluctuating conditions. By addressing these challenges proactively, operators can reduce the likelihood of performance degradation and ensure that the compressor operates consistently over time.

What are the improvements in the main unit efficiency of a micro-oil twin screw air compressor compared to a traditional twin screw compressor?

Is it common for micro-oil twin-screw air compressors to experience performance degradation after prolonged operation at full load?

Your email address will not be published. Required fields are marked *

A dedicated after-sales service department is established, consisting of a professional sales team and skilled technical engineers. They are committed to providing year-round support, traveling to customer locations to deliver prompt and high-quality service.

Tel:86-0570-7221666

E-mail:[email protected]

Add: No.2 Qiming Road, Zhejiang Longyou Economic Development Zone, Mohuan Township, Longyou County, Quzhou City, Zhejiang Province, China