What is the Energy Efficiency Level of a Micro-Oil Twin Screw Single-Stage Compressor?

Overview of Micro-Oil Twin Screw Single-Stage Compressors

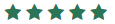

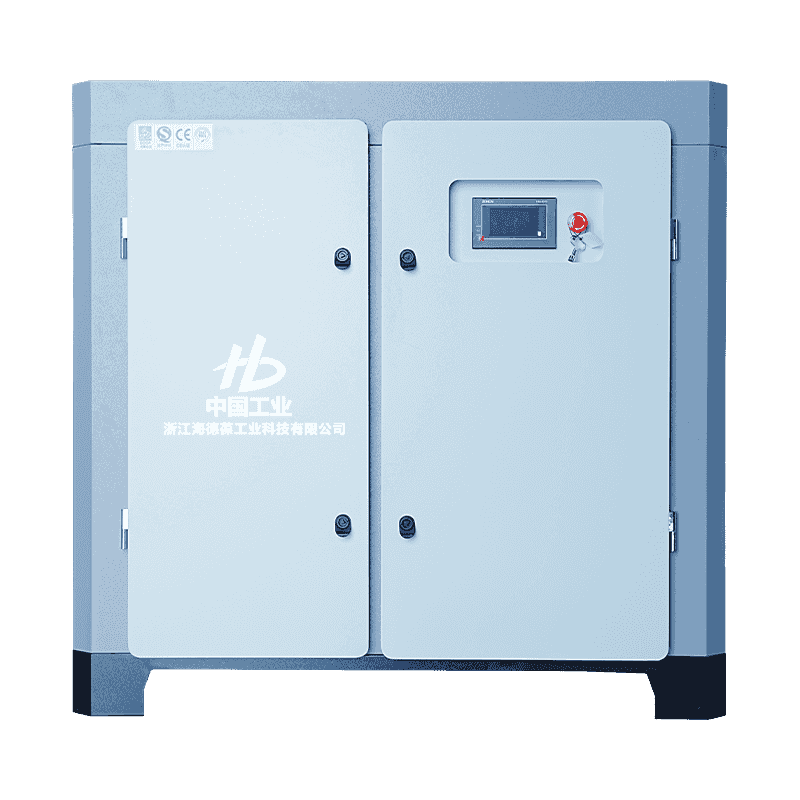

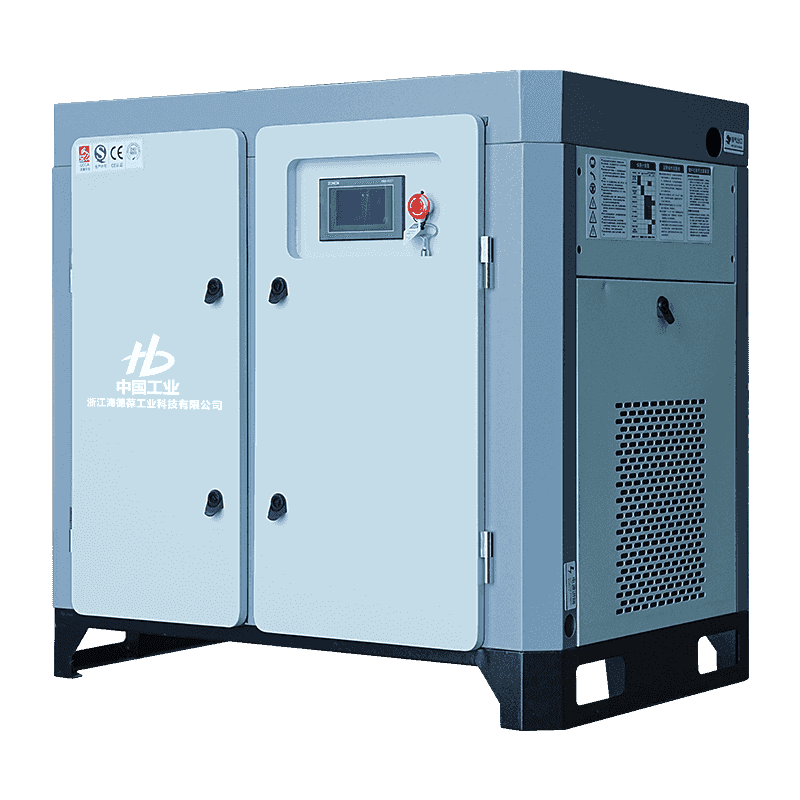

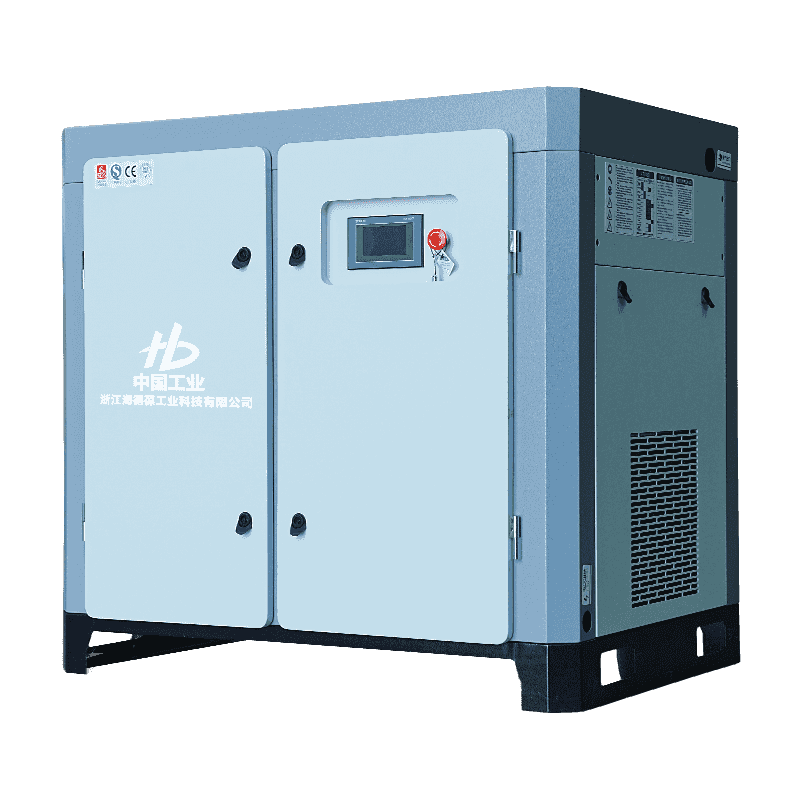

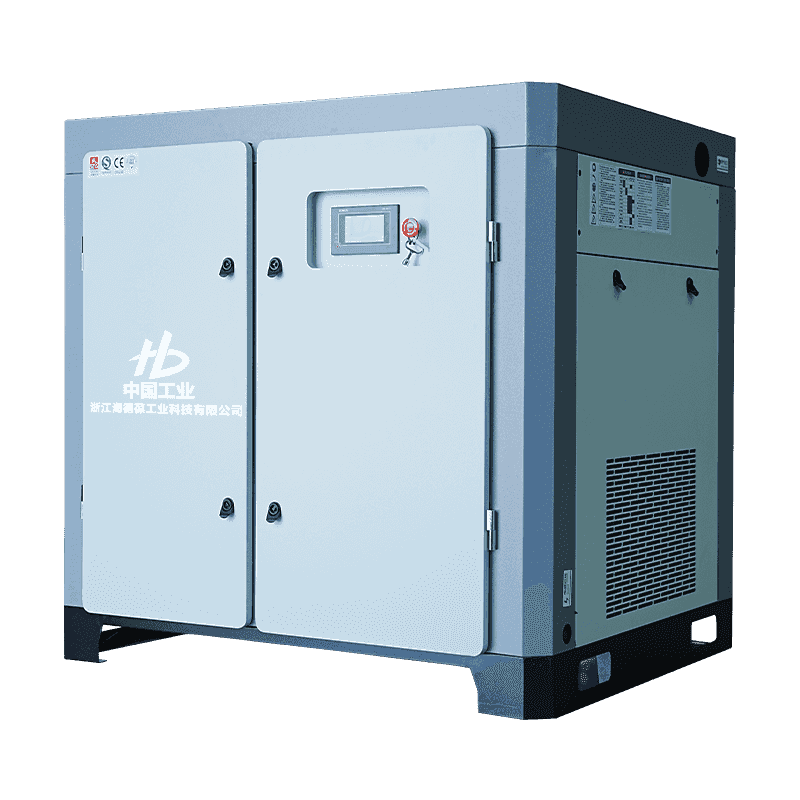

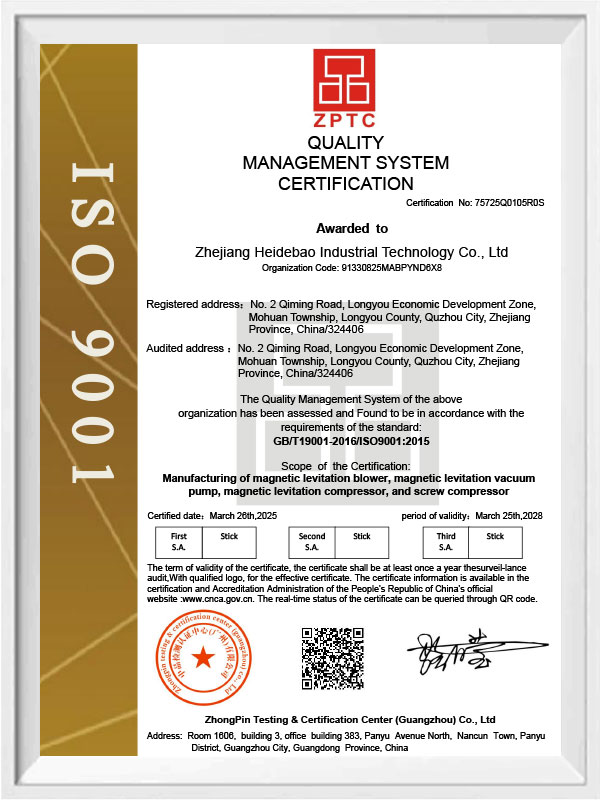

The micro-oil twin screw single-stage compressor is a widely used type of air compressor that integrates efficiency, stability, and durability within industrial systems. Zhejiang Haidebao Industrial Technology Co., Ltd., located in Quzhou City, Zhejiang Province, specializes in the research, design, and production of aerodynamic components for gas compressor systems. The company’s engineering approach focuses on energy-efficient designs that meet modern industrial requirements for air compression. A micro-oil twin screw compressor operates by injecting a small quantity of lubricating oil into the compression chamber to reduce friction, enhance sealing, and improve heat dissipation. This technology allows for effective energy utilization and smooth operation even under continuous load conditions, which contributes to its recognized energy efficiency level in various industrial sectors.

Working Principle and Energy Utilization

The energy efficiency of a micro-oil twin screw single-stage compressor is primarily determined by its mechanical design and thermodynamic performance. The twin screw mechanism consists of a pair of intermeshing rotors that compress air as it moves through the chamber. The injection of micro amounts of oil helps seal the clearances between the rotors and the housing, minimizing leakage losses. This oil also serves as a cooling medium, absorbing the heat generated during compression and maintaining an optimal temperature balance. As a result, less energy is wasted in overcoming friction and heat buildup, which directly improves the compressor’s overall efficiency. Zhejiang Haidebao Industrial Technology Co., Ltd. adopts precision machining and aerodynamic optimization in rotor design to ensure consistent energy performance across varying operational loads.

Energy Efficiency Classification and Standards

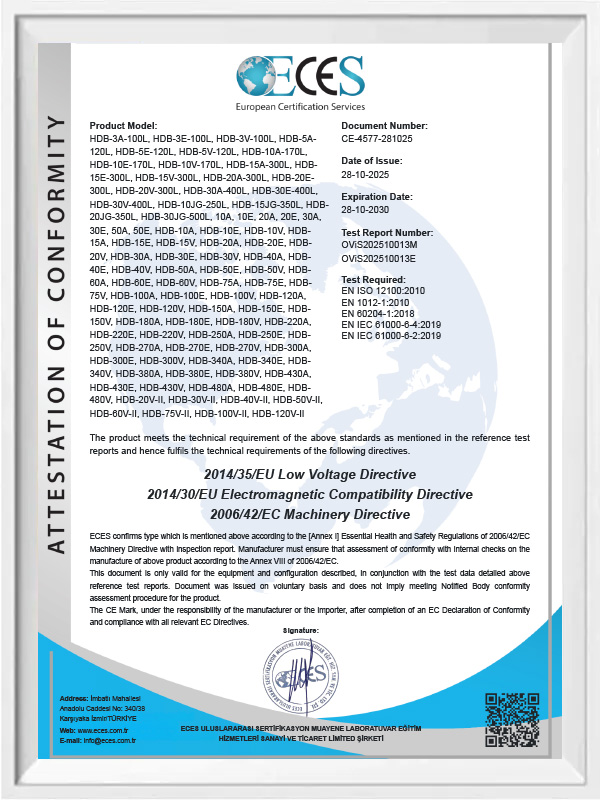

In industrial air compression, energy efficiency levels are usually evaluated based on specific energy consumption (SEC), which measures the amount of energy required to produce a unit volume of compressed air. Micro-oil twin screw single-stage compressors typically achieve an efficiency level that aligns with national and international standards such as ISO 1217 and GB 19153. These compressors are known to maintain stable performance across different pressure ranges, often within the 7–13 bar range. Zhejiang Haidebao Industrial Technology Co., Ltd. manufactures its compressors to comply with stringent efficiency requirements by optimizing rotor profiles, using high-precision bearings, and incorporating advanced oil control systems. Such design strategies help the equipment maintain a favorable balance between airflow output and power input, thereby enhancing operational sustainability.

Influence of Design and Materials on Energy Efficiency

The efficiency of a micro-oil twin screw compressor is heavily influenced by the quality of its materials and internal design. High-grade rotor materials with precise surface finishes minimize air leakage and mechanical wear, both of which can reduce energy efficiency over time. The single-stage configuration used in these compressors simplifies the compression process, lowering mechanical losses associated with multi-stage systems. In addition, modern micro-oil injection systems control the exact volume and distribution of oil within the compression chamber, ensuring effective lubrication without excessive fluid drag. Zhejiang Haidebao Industrial Technology Co., Ltd. emphasizes precision engineering and the use of advanced materials to enhance the compressor’s thermal balance and minimize energy waste during continuous operation.

Performance Comparison Table

| Parameter |

Micro-Oil Twin Screw Compressor |

Oil-Free Twin Screw Compressor |

| Compression Stage |

Single Stage |

Single or Multi-Stage |

| Lubrication Type |

Micro-Oil Injection |

Oil-Free |

| Cooling Efficiency |

High due to oil cooling |

Moderate, depends on air or water cooling |

| Specific Energy Consumption (SEC) |

Low to Medium (5.5–7.0 kW/m³/min) |

Higher (6.5–8.0 kW/m³/min) |

| Maintenance Requirement |

Medium |

High |

| Typical Application |

General industrial use, mechanical manufacturing |

Food, pharmaceutical, and electronics industries |

Impact of Operating Conditions on Energy Efficiency

The operating environment significantly affects the energy efficiency of a micro-oil twin screw single-stage compressor. Factors such as ambient temperature, humidity, and inlet air quality can influence air density and the compressor’s thermal load. Maintaining optimal operating conditions, such as clean filters and consistent oil levels, ensures that the compressor continues to deliver efficient performance. Zhejiang Haidebao Industrial Technology Co., Ltd. designs its compressor systems with advanced control mechanisms that automatically adjust the compression ratio and oil flow based on real-time operational data. These control systems enhance adaptability to environmental variations and maintain consistent efficiency even during fluctuating workloads.

Maintenance and Long-Term Energy Efficiency

Proper maintenance plays an essential role in sustaining the energy efficiency of a micro-oil twin screw compressor over its lifespan. Regular oil replacement, filter cleaning, and alignment checks prevent performance degradation and unnecessary energy losses. Belt alignment, rotor clearance, and bearing lubrication should be periodically inspected to maintain smooth operation. Zhejiang Haidebao Industrial Technology Co., Ltd. provides maintenance support and technical services aimed at optimizing compressor performance and extending operational life. Through preventive maintenance and system monitoring, the compressor maintains stable airflow output and avoids energy waste caused by wear, air leakage, or oil contamination.

Conclusion on Efficiency Level

Overall, the energy efficiency level of a micro-oil twin screw single-stage compressor is typically categorized within a high-performance range due to its reduced internal losses, controlled oil injection, and consistent pressure output. These compressors provide a practical balance between efficiency, reliability, and operational cost. Zhejiang Haidebao Industrial Technology Co., Ltd. applies advanced aerodynamic and mechanical engineering principles to improve the compressor’s energy utilization ratio and meet modern industry requirements. With continuous technological refinement, micro-oil twin screw single-stage compressors remain an effective solution for industries seeking stable and energy-efficient compressed air systems.

Does the Micro-Oil Twin Screw Single Stage Compressor Support Frequency Conversion Control to Achieve On-Demand Gas Supply?

Overview of Frequency Conversion Technology in Compressors

Frequency conversion control, also known as variable frequency drive (VFD) technology, is an advanced method used to regulate the operating speed of compressors based on real-time air demand. This technology allows the motor to adjust its rotational speed according to the system's pressure requirements, thereby achieving on-demand gas supply. Zhejiang Haidebao Industrial Technology Co., Ltd., located in Quzhou City, Zhejiang Province, specializes in the research, development, and manufacturing of high-quality aerodynamic products for gas compressor systems. The company incorporates frequency conversion technology into its micro-oil twin screw single-stage compressors to enhance efficiency and adaptability across diverse industrial applications. By precisely matching compressor output with air consumption, frequency conversion control minimizes energy waste and helps maintain a stable air supply.

Principle of Frequency Conversion Control

The working principle of frequency conversion control in a micro-oil twin screw single-stage compressor involves the use of an inverter to adjust the frequency and voltage supplied to the compressor’s motor. When air demand decreases, the inverter reduces the motor speed, resulting in lower energy consumption and reduced mechanical stress. Conversely, when demand rises, the motor speed increases to deliver the necessary airflow. This dynamic adjustment ensures the compressor operates within optimal efficiency ranges. Zhejiang Haidebao Industrial Technology Co., Ltd. designs its compressor systems with precise electronic controls that continuously monitor system pressure, airflow, and motor load. These systems integrate seamlessly with frequency converters to provide accurate on-demand performance without frequent start-stop cycles, which can extend equipment lifespan and reduce operational costs.

Advantages of Frequency Conversion Control

Micro-oil twin screw single-stage compressors equipped with frequency conversion control offer several practical advantages for industrial users. The most notable benefit is the ability to deliver compressed air exactly when needed, preventing excessive energy use during low-demand periods. This functionality significantly reduces power consumption and operating costs over time. Additionally, frequency conversion provides smoother motor acceleration and deceleration, minimizing mechanical shock to components and reducing maintenance frequency. Zhejiang Haidebao Industrial Technology Co., Ltd. integrates this control method to achieve more consistent pressure regulation, avoiding fluctuations that may affect downstream equipment. The result is a balanced and efficient air supply system capable of maintaining reliability even under variable load conditions.

Application of Frequency Conversion in Micro-Oil Twin Screw Compressors

In micro-oil twin screw single-stage compressors, frequency conversion control works in conjunction with the compressor’s oil injection and rotor synchronization system. The micro-oil injection stabilizes internal temperatures, reduces leakage, and maintains efficiency, while the variable frequency drive adjusts motor speed to align airflow output with consumption. Zhejiang Haidebao Industrial Technology Co., Ltd. applies this technology to compressors used in industries such as electronics, metallurgy, and precision manufacturing, where air demand can fluctuate throughout production cycles. The system’s control algorithm dynamically adjusts air delivery, ensuring that only the necessary amount of compressed air is generated at any given moment. This intelligent operation minimizes energy losses and enhances the overall efficiency of the gas compression process.

Performance Comparison Table

| Parameter |

Fixed-Speed Compressor |

Frequency Conversion Compressor |

| Motor Operation |

Constant speed regardless of demand |

Variable speed based on air demand |

| Energy Consumption |

High during low-demand periods |

Reduced energy use due to adaptive control |

| Pressure Stability |

Fluctuates between load and unload cycles |

Stable and continuous pressure control |

| Maintenance Requirements |

Higher due to frequent start-stop operation |

Lower because of smoother load transitions |

| Service Life |

Moderate, dependent on operational cycles |

Extended due to reduced mechanical stress |

Integration of Frequency Conversion Control with System Monitoring

To ensure reliable performance, Zhejiang Haidebao Industrial Technology Co., Ltd. integrates frequency conversion control with advanced system monitoring and feedback mechanisms. These include sensors that track temperature, pressure, and vibration, allowing the compressor control system to respond instantly to any changes in air demand or operating conditions. The intelligent control panel displays real-time operating data, enabling users to adjust parameters and optimize performance easily. This combination of digital monitoring and variable frequency operation enhances the efficiency of compressor management, allowing users to maintain steady gas supply without overloading the system. Furthermore, the adaptive control feature helps reduce operational noise and heat output, contributing to a more stable working environment.

Impact on Energy Efficiency and Operational Costs

Implementing frequency conversion control in a micro-oil twin screw single-stage compressor greatly impacts energy efficiency and long-term operational costs. Because the compressor operates only at the required load, energy savings can reach up to 30–40% compared to traditional fixed-speed models. Reduced start-stop cycling also lowers the mechanical wear on key components, such as bearings and rotors, extending their service life. Zhejiang Haidebao Industrial Technology Co., Ltd. incorporates high-efficiency inverters and precision-engineered motors to maximize the performance of its compressors under variable frequency operation. The combination of efficient energy utilization, stable airflow, and reduced mechanical losses makes this configuration suitable for industries seeking sustainable and cost-effective compressed air solutions.

Conclusion on Frequency Conversion Control Capability

The micro-oil twin screw single-stage compressor developed by Zhejiang Haidebao Industrial Technology Co., Ltd. fully supports frequency conversion control to achieve on-demand gas supply. Through precise electronic regulation, real-time monitoring, and adaptive motor control, the system efficiently matches air production to consumption needs. This not only enhances operational efficiency but also contributes to energy conservation and long-term system stability. The integration of micro-oil lubrication and variable frequency technology provides a balanced solution for modern industrial applications, ensuring reliable gas delivery while maintaining high energy efficiency and consistent performance.

English

English Español

Español عربى

عربى