Does a micro-oil twin screw air compressor require additional after-treatment equipment?

Understanding Whether Micro-Oil Twin Screw Air Compressors Require After-Treatment Equipment

Determining whether a micro-oil twin screw air compressor requires additional after‑treatment equipment is essential for ensuring stable air quality across a wide range of industrial applications. Micro‑oil systems inject a controlled amount of lubricating oil into the compression chamber, enabling effective sealing, cooling, and lubrication. However, this design also introduces a small quantity of oil into the compressed air, making purification measures an important consideration. Haidebao specializes in high specification aerodynamic products for gas compressor system research, design, manufacturing, marketing, and service. With this background, the company provides insights into whether after‑treatment equipment is necessary and how system configurations should be evaluated.

Characteristics of Micro-Oil Twin Screw Compression

A micro‑oil twin screw compressor relies on injecting a minimal amount of oil into the compression process, helping maintain efficiency, stability, and mechanical durability. While the amount of oil entering the compressed air is controlled, it does not reach oil‑free levels by default. This means that downstream purification normally becomes part of the complete solution. Understanding how oil behaves within the system is key: some oil adheres to mechanical surfaces, some remains in mist form, and some may vaporize depending on the operating temperature. Haidebao’s engineering expertise ensures that core compression components are designed to stabilize performance, but evaluating whether after‑treatment equipment is required depends on application purity needs rather than compressor structure alone.

Industrial Standards Relevant to Micro-Oil Air Systems

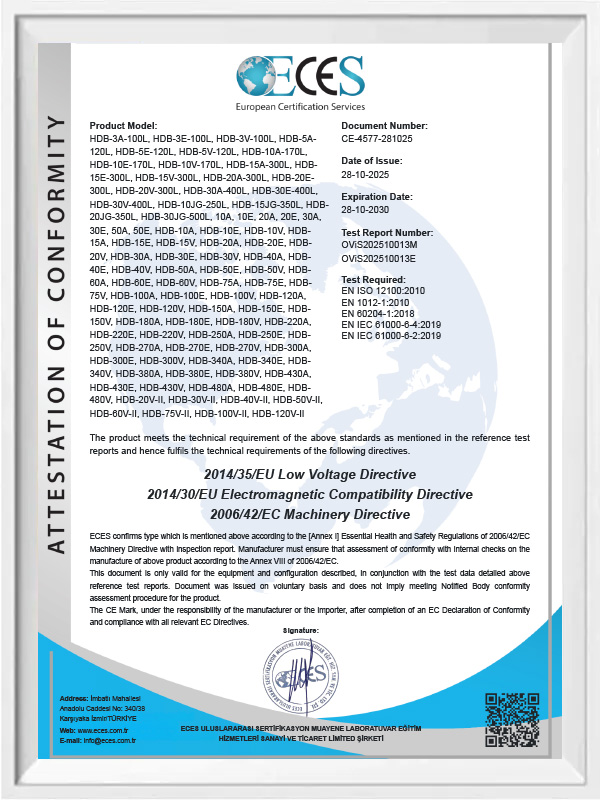

Compressed air purity is typically measured according to ISO 8573‑1, which classifies allowable limits for particles, water, and total oil content. Micro‑oil compressors generally achieve oil content levels suitable for Class 2 or Class 3 when used with basic internal separation components. However, processes such as precision electronics, pharmaceuticals, food production, or laboratory applications may demand cleaner air that falls within Class 1 or a customized specification established between user and manufacturer. Haidebao supports system design aligned with these standards, helping customers match compressor capabilities with appropriate purification solutions.

| ISO 8573-1 Category |

Typical Requirement |

Achievable with Micro-Oil Compressor Alone |

| Particles |

Varies by Class 1–6 |

Filter dependent |

| Water |

Dew point control |

Requires dryer |

| Total Oil Content |

Class 1 ≤ 0.01 mg/m³ |

Needs after-treatment |

The table shows that achieving higher levels of purity typically requires additional system components beyond the compressor. Haidebao provides guidance to ensure treatment equipment is correctly matched with compressor output characteristics.

Role of After-Treatment Equipment in Micro-Oil Systems

After‑treatment equipment helps remove oil aerosols, oil vapors, moisture, and particles from the compressed air. Common components include coalescing filters, activated carbon filters, refrigeration dryers, and adsorption dryers. Coalescing filters reduce oil mist, while carbon filters absorb vapor‑phase oil, making the system suitable for more sensitive applications. In micro‑oil systems, these components often function as part of a planned air purification chain rather than optional accessories. Haidebao’s system integration experience supports customers in selecting compatible combinations of filters and dryers to achieve specific purity outcomes without unnecessary oversizing or mismatching.

Evaluation Based on Application Requirements

Whether additional treatment equipment is necessary depends primarily on the intended use of the compressed air. Applications such as pneumatic tools, packaging equipment, or general industrial automation may operate effectively with basic filtration and a standard drying unit. In contrast, environments requiring reduced oil content or stable dew points typically require more comprehensive purification. Users should map their operational requirements to the corresponding purity class and then determine what treatment components are needed to achieve that class consistently. Haidebao provides detailed assessments to help customers identify appropriate treatment stages based on their production processes.

System-Level Considerations Affecting Treatment Necessity

System factors such as ambient environment, piping layout, flow demand fluctuations, and temperature conditions can influence air purity. Even if the compressor’s internal oil removal system is functioning correctly, downstream piping may accumulate residue if after‑treatment is insufficient. Regular inspection of filters, separators, dryers, and condensate management components is also critical to maintaining purity levels. Haidebao’s service teams assist users with system evaluation, ensuring that compressor performance aligns with treatment equipment efficiency.

Practical Recommendations for Users

To determine whether after‑treatment equipment is necessary, users should begin by confirming their required air quality class, reviewing oil content specifications, conducting periodic purity testing, and evaluating the condition of downstream components. If testing results show oil content or moisture levels above acceptable thresholds, installing or upgrading purification devices becomes essential. Haidebao provides technical support for designing complete air systems, enabling users to maintain compressed air quality aligned with operational needs. Through careful assessment and system‑level coordination, users can ensure that micro‑oil twin screw compressors perform reliably while meeting required purity standards.

How to evaluate the stability and durability of a micro-oil twin screw air compressor?

Key Understanding of Stability and Durability Assessment

Evaluating the stability and durability of a micro-oil twin screw air compressor requires understanding how its mechanical structure, lubrication system, and operating conditions influence long-term performance. Micro-oil compressors rely on controlled oil injection to help maintain rotor sealing, temperature balance, and mechanical protection. Although the injected oil provides operational stability, assessment should go beyond the compressor’s internal design. Haidebao specializes in high specification aerodynamic products for gas compressor system research, design, manufacturing, marketing, and service, offering insights into how users can systematically evaluate compressor behavior across varying environments. A reliable evaluation considers operating patterns, component materials, system load distribution, and maintenance practices.

Mechanical Structure and Rotor Integrity

The foundation of stability in a micro-oil twin screw compressor lies in the rotor design, rotor coating, and the precision of rotor alignment. Micro-oil designs help reduce wear by providing an oil film that stabilizes rotor movement. Durability evaluation should focus on long-term wear of rotor surfaces, gear alignment accuracy, and bearing load capacity. Even though the oil provides lubrication, improper operation or long-term stress can lead to increased friction or misalignment. Haidebao’s engineering capabilities ensure that rotor profiles and material selection support steady operation, but users must still monitor structural behavior through scheduled inspections.

Lubrication Quality and Oil Management System

The lubrication system plays a major role in determining stability. Oil quality, temperature management, and circulation effectiveness influence the protection of internal components. Low-quality oil or delayed replacement may cause gradual degradation in performance. An effective oil separation system reduces contamination risks, while stable lubrication flow supports rotor balance and bearing life. Users evaluating durability should examine oil life indicators, separation efficiency, and temperature trends during continuous operation. Haidebao’s product development experience ensures that these elements are integrated into system design to help maintain balanced operating conditions.

| Evaluation Item |

Assessment Focus |

Impact on Durability |

| Oil Quality |

Viscosity stability |

Influences wear rate |

| Temperature Control |

Cooling effectiveness |

Affects bearing and rotor life |

| Separation Efficiency |

Mist and vapor removal |

Protects downstream components |

This table highlights essential areas users should review when analyzing long-term lubrication stability.

Load Conditions and Operating Environment

Compressor stability is strongly affected by load variations. Frequent start-stop cycles, rapid pressure fluctuations, or extended full-load operations may change mechanical behavior over time. Durability evaluation should consider whether the compressor operates near its rated capacity and whether environmental factors such as temperature, dust, or humidity affect system performance. Haidebao’s expertise in aerodynamic analysis supports configurations optimized for stable load distribution, but users should still track key indicators such as temperature rise, pressure balance, and vibration levels.

Control System Performance

Advanced micro-oil compressors incorporate control systems that regulate pressure, temperature, and motor behavior. Evaluating stability requires analyzing how accurately the control system manages fluctuations and how quickly it responds to load changes. Durability also depends on whether sensors and regulators maintain consistent accuracy over time. Users should examine operating logs, alarm history, and controller calibration records. Haidebao integrates system monitoring functions that support real-time evaluation, helping users maintain steady operation across varying conditions.

Piping Configuration and System Integration

Even a well-designed compressor may experience instability if installed within an improper system configuration. Long piping runs, inadequate ventilation, or incompatible downstream equipment may introduce unnecessary stress. Evaluating durability includes reviewing piping cleanliness, condensate management, vibration transmission, and airflow restriction. Proper integration reduces unnecessary mechanical load on the compressor. Haidebao provides system-level guidance to help users match compressors with suitable filtration, drying, and distribution systems.

Maintenance Practices and Service Predictability

Durability depends strongly on how consistently maintenance procedures are followed. Filter replacement intervals, oil changes, bearing inspections, and cleaning routines influence long-term stability. Predictive maintenance strategies, such as vibration monitoring or temperature trend analysis, provide early warnings before component degradation affects stability. Haidebao offers support across the service lifecycle, helping users establish maintenance schedules tailored to their operating conditions and ensuring that component wear is detected at an early stage.

Practical Steps for Evaluating Stability and Durability

To effectively evaluate a micro-oil twin screw compressor, users should review historical performance data, monitor key indicators such as temperature and vibration, inspect lubrication efficiency, and assess system-level integration. Detailed observation of rotor condition, bearing alignment, and separation system behavior also contributes to accurate durability assessment. Haidebao’s experience in aerodynamic product development and system engineering provides customers with the necessary guidance to evaluate long-term performance. Through structured monitoring and periodic testing, users can ensure that stability remains consistent and that the compressor meets operational expectations over its service life.

English

English Español

Español عربى

عربى